The Lean Six Sigma toolset makes use of a variety of process maps. Each of these diagrams aids in understanding the flow and making it clear how the process works.

Although detailed mapping is key to good process improvement, I would venture that properly constructing a high-level map first, can be even more instrumental.

Meet the SIPOC

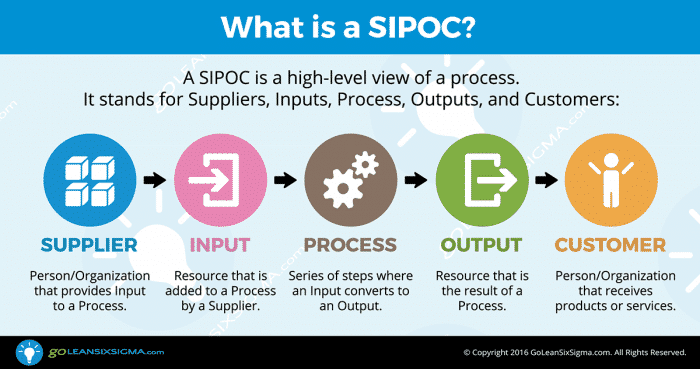

Most models include the SIPOC diagram in the Define Phase of DMAIC projects. SIPOC stands for:

- Suppliers

- Inputs

- Process

- Outputs

- Customers

By definition, it is a high-level view of a process. Typically, the process portion of this tool contains 5-7 steps. With so few steps, it provides only minimal detail on the process itself. Most improvement project require a lower level, more detailed flow chart to truly understand how the process currently operates.

So, why include this high-level map? What is the purpose of creating a SIPOC diagram? The original improvement process had only four phases:

The Define Phase was added later to aid in clarifying the scope of improvement projects. The SIPOC diagram is part of that scoping phase. It serves as a framing tool for the process being improved.

It serves as a framing tool for the process being improved.

Within the SIPOC, you define where the process starts and stops. You also list the Output and the Customer. As a helpful check, it’s good to ask if the Output of the SIPOC is the result of the last step of the process segment. Does the Customer receive this Output?

The SIPOC Helps Make Process Improvement Easier

I worked with a company which commissioned a team to solve a key source of customer complaints – late shipments. The team worked its way through the Define and Measure Phases and reported their findings. According to their data, none of the shipments technically left the plant late. When asked about the customer complaints, they responded that the problem must be with the carrier. It turned out that the team was comparing the due date to the date it was shipped. However, the customer was comparing the due date to the date it was received. The plant did not have an easy way to get this data, so they recorded the available data rather than the data the customer cared about.

This is an example of a SIPOC gone awry. If the last step in a SIPOC is, “Ship the product”, then the output must be a shipped product. But in this case, the one who received the product was the carrier, which was not the customer of interest in this process. There was an easy way to fix this. If we added another step which is to “Deliver the product,” then the customer would be the recipient as we had intended. Making this change placed the carrier inside the process, not outside it. This is an important distinction to make in order to address the true customer complaint.

This is an important distinction to make in order to address the true customer complaint.

The obvious response from the team was, “But we have no control over the carrier’s process.” While that might be technically true, my question to them was, “Who is the carrier from the customer’s perspective? Does our customer see the carrier as their supplier or as part of us, the manufacturer of the goods being delivered?” Most of them agreed, the manufacturer was viewed as the supplier which was why the complaint was filed with us, and not the carrier.

The #1 Quality Problem

Having worked with dozens of improvement teams over the years, I often tell people that I have discovered the number one quality problem across all organizations. People lean forward in anticipation, but they’re surprised by my answer – Them! They are the number one problem for many processes. If they, the supplier, the customer, etc., would just do something differently, we wouldn’t have so many problems.

I often tell people that I have discovered the number one quality problem across all organizations.

Now, this might sound trivial – a play on words, but it is key to understanding process improvement. An improvement team can rarely change Them. No one wants an outsider coming in to change how their process works. But, by properly framing the process, and adding “Deliver the product” in the example above, you change Them to Us. Understanding how the carrier’s process worked and understanding the interface from our shipment to their delivery was key to reducing the number of customer complaints.

We can repeat the same scenario on the front end of the SIPOC. I have seen improvement projects where the most problematic source of variation was the supplier. In these cases, wouldn’t the SIPOC best serve the project if we moved the first step further upstream in the process? If we brought the supplier into the process, we would immediately change them to us.

3 Key Questions to Ask Before Getting Started

Knowing where to place these boundaries is not as simple as it looks. It is why the SIPOC is central to properly scoping the project. It answers some key questions:

- Is the project focused on the appropriate customer?

- Do we understand what is critical to the customer and how to measure it?

- Does that measurement show significant sources of variation within the process?

Building a SIPOC that properly addresses these three questions is critical to ensuring that we truly deliver improvement for the customer.

asking these questions and getting the SIPOC framed to the issue at hand aids in properly determining the project team members

Finally, asking these questions and getting the SIPOC framed to the issue at hand aids in properly determining the project team members. Certainly you want team members who can represent the process from beginning to end. From our example, having someone that understood the carrier’s process was critical to the improvement efforts.

There is never a “right” answer for what process should be studied, but aligning the SIPOC to the proper customer and their key metric can greatly improve your improvement efforts.