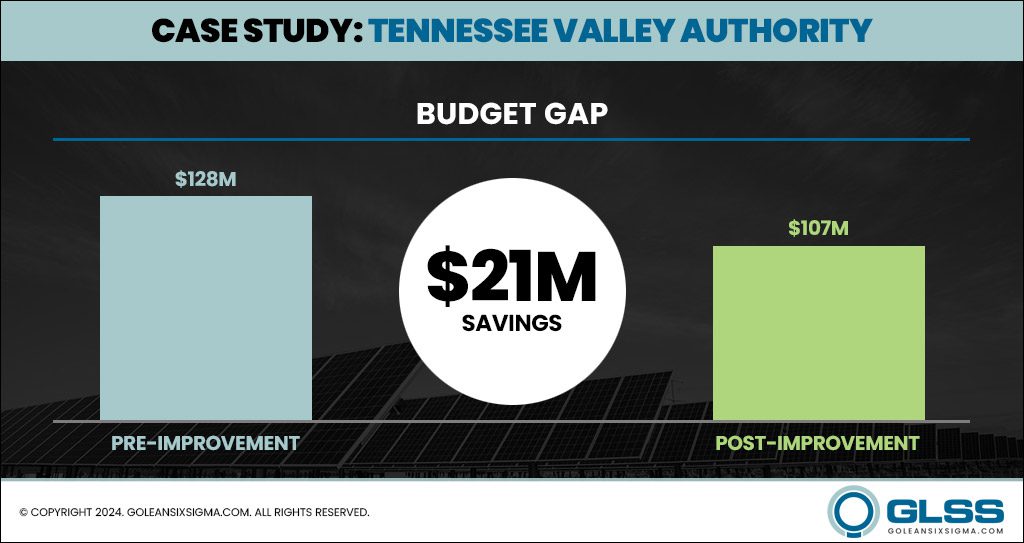

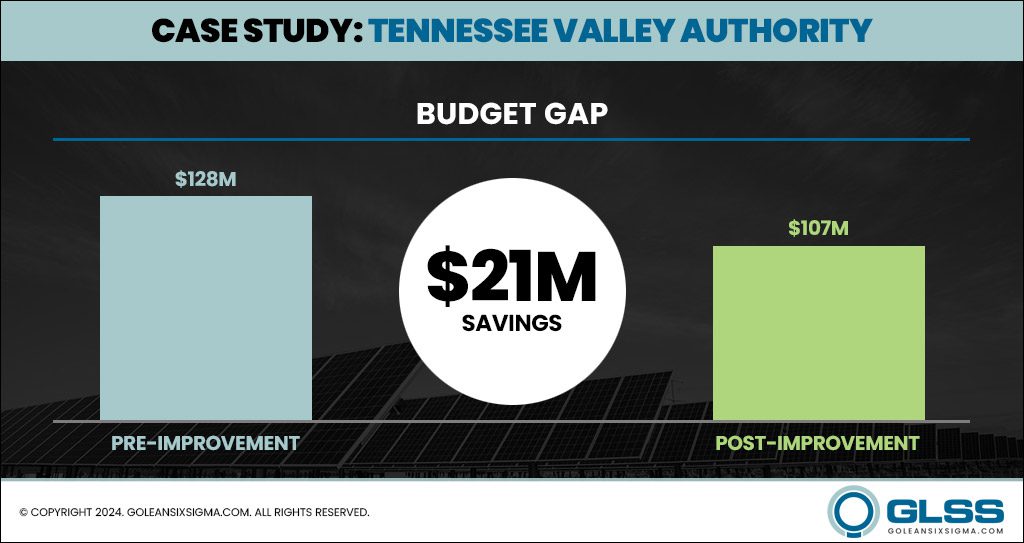

Closing The Budget Gap By $21M With Lean Six Sigma

Home » Case Study » Tennessee Valley Authority Closes The Budget Gap By $21M With GLSS

Tennessee

Government

Energy

$21M

PROJECT SUMMARY

From a quickly evolving power landscape to greater regulatory requirements, Tennessee Valley Authority (TVA) and other electricity providers across the country are being pushed to do far more with far less.

As resources become limited and obstacles grow by the day, how can these vital suppliers manage to literally keep the lights on while they strive to attain maximum efficiency? They must transform into a true community of problem solvers steadfastly devoted to a widespread culture of operational excellence and continuous process improvement.

Our online Lean Six Sigma training makes it easy for any public utility to reduce costs and improve efficiencies without jeopardizing its core mission. By empowering employees to problem solve, GoLeanSixSigma.com’s courses enabled the TVA to close a substantial budget gap by $21 million.

Signed into existence by Franklin Roosevelt nearly 90 years ago, the TVA remains a vital source of power for 9 million people across seven southeast states. But changes to the power landscape in coal, gas, and hydro generating fleets left the agency with a $128M budget gap to close over a 4-year period. It was painfully obvious that something had to change.

Continuous Improvement wasn’t a new concept at the TVA. By the time GoLeanSixSigma.com got involved, there had been many one-off efforts. Consultants had come and gone, and projects had even been completed. But every single one failed to deliver the desired results.

Those disappointments created a stigma around Continuous Improvement that wasn’t easy to shake, making Lean Six Sigma training a fairly hard sell – at least initially.

Black Belt Bill Guill, a 27-year veteran of the TVA, had been recruited by executives to become the Fleet Continuous Improvement (CI) Manager.

Over the course of his career, he had worked at the coal fired generating plants as a laborer, operator, supervisor, plant manager, and in the office of the CEO for several change initiatives. His diverse corporate and plant operational experience provided the credibility to connect with people at all levels of the organization, from the frontline employees to executives. One of Bill’s main messages to employees was that they were already doing continuous improvement — they just weren’t taking credit.

“Even as we go to work, we figure out the most efficient route,” he noted. “We’re wired as humans to do things most efficiently.”

Because TVA employees were already trained to problem-solve and troubleshoot every day, Bill was able to leverage that to focus on Continuous Improvement (CI) Quick Wins. It wasn’t long before front-line employees were getting excited about finding savings and getting recognition for the improvements they initiated.

In order to integrate Continuous Improvement into their daily work, Bill focused on getting one CI (Continuous Improvement) Quick Win a month that was sent out across the fleet for replication. They tracked each of these improvements on the fleet CI Scorecard.

From there he began working on sustainability by integrating Continuous Improvement into key meetings at the plant, fleet, and corporate levels. During these meetings, executives, managers, and employees spent time discussing CI Quick Wins and ideas. They also integrated Continuous Improvement goals into the Performance Management program as part of the employee-specific goals for the year.

Bill had people going through training, conducting improvement projects, and communicating the wins all at the same time. The robust oversight metrics in the scorecards drove the right behaviors and allowed him to monitor their performance to ensure improvements were aligned with fleet strategy.

“My executive team provided great support and allowed me to use my boots-on-the-ground experience when developing the strategy and tactical execution plan,” Bill remembered.

The combination of GoLeanSixSigma.com’s online Lean Six Sigma training, Bill’s expertise and credibility, and the strong backing from execs worked exceptionally well! In only the first year of CI deployment, TVA Power Operations built a solid Continuous Improvement foundation by training 93% of the workforce. Those 1,845 employees were able to leverage their training to identify more than 600 projects that helped close the TVA’s budget gap by $21 million.

Don’t let process problems hold you back!

By empowering employees to problem solve, GoLeanSixSigma.com’s online Lean Six Sigma training puts a culture of operational excellence and continuous process improvement within easy reach of any organization.

Contact us to get started!