How do you get to the root of the problem? How do you determine the true source of the issue so you can solve the problem for good? That is the crux of an improvement effort and the key focus of the Analyze Phase. This phase doesn’t always get the attention it deserves, but it’s the heart and soul of problem solving.

Teams often initiate projects with assumptions about what’s causing process issues. If preconceived notions go unchecked, teams can jump to solutions before verifying the true root causes. The result? Implementing solutions that fail to resolve the problem.

This wastes time, consumes resources, creates more variation and often causes new problems. The ideal is to study the process and the data to find clues to potential root causes. The idea is to develop hypotheses as to why problems exist and then work to prove or disprove those hypotheses.

Verification can involve data analysis, process observations or tests to turn potential causes “off and on.” The goal is to get crystal clear on the sources of process problems before considering solutions. This is the value and power of the Analyze Phase.

Closely Examine the Process

After conducting a Process Walk, creating high-level and detailed process maps and collecting process data, the team is able to scrutinize the process and reveal the pain points. This allows the team to take advantage of the collective wisdom of the process participants. They can expand the depth and breadth of their process knowledge by conducting any of the following:

- Time Analysis: focuses on the actual time work is being done in the process versus the time spent waiting. What teams discover is that whereas people are 99% busy, “things” are 99% idle.

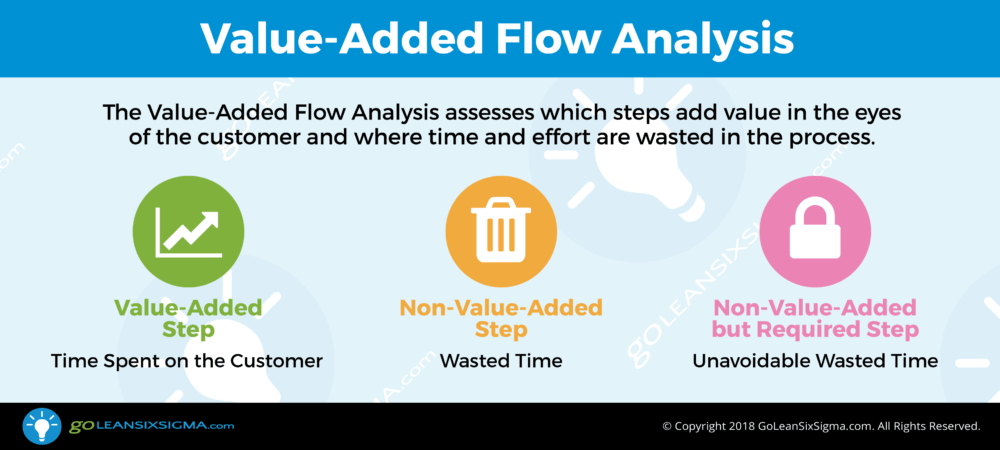

- Value Added Analysis: adds another dimension of discovery by looking at the process through the eyes of the customer to uncover non-value-adding steps and the cost of doing business.

- Value Stream Mapping: combines process data with a map of the value-adding steps to help determine where Waste can be removed.

Tools: Value Stream Map and Value Added Flow Analysis

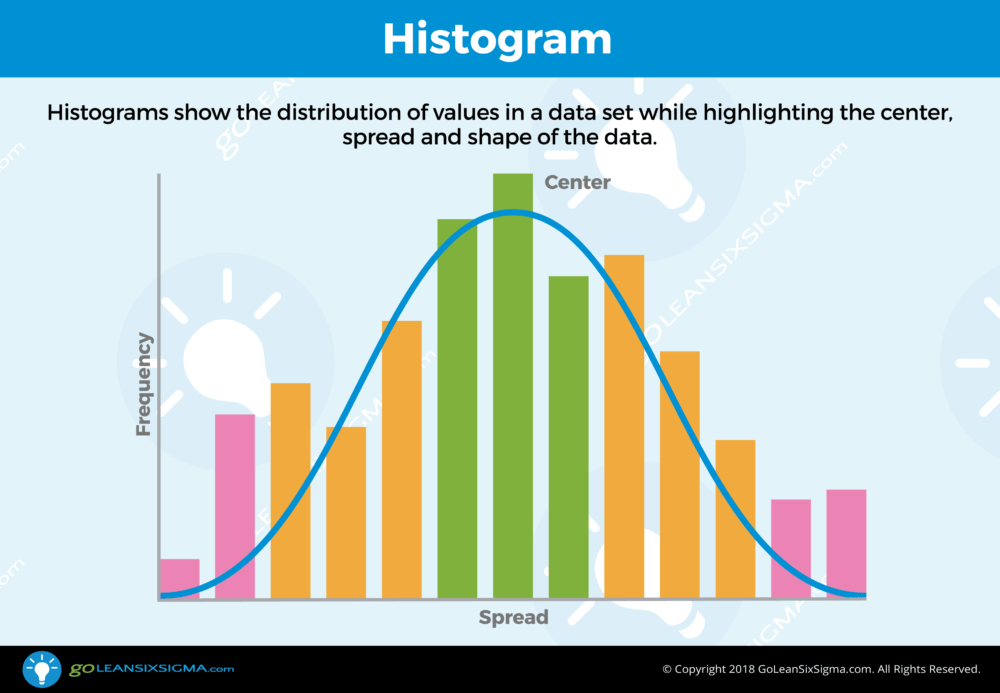

Graphically Display the Data

After collecting data, the team is able to display it using charts and graphs providing visual clues to process problems. Transforming spreadsheets of numbers into revealing visuals allows the team to easily communicate their findings to leadership and other process participants. Selecting the right charts and graphs provides the team with valuable insights about the causes of process issues.

Tools: Run Charts, Histograms, Pareto Charts and Box Plots

Look for What Might Be Causing the Problem

After combining both Process Analysis and Data Analysis to uncover clues, the team adds their findings to the Cause & Effect or Fishbone Diagram. By continuously contributing to this living document, the team builds on the collective wisdom of process participants. Using the 5 Whys as a companion tool guides team members to drill past symptoms to the root causes of process issues. This helps the team dig down to the vital few causes of lost time, defects and waste in the process.

Tools: Fishbone Diagram and the 5 Whys

Webinar: How to Use a Fishbone Diagram

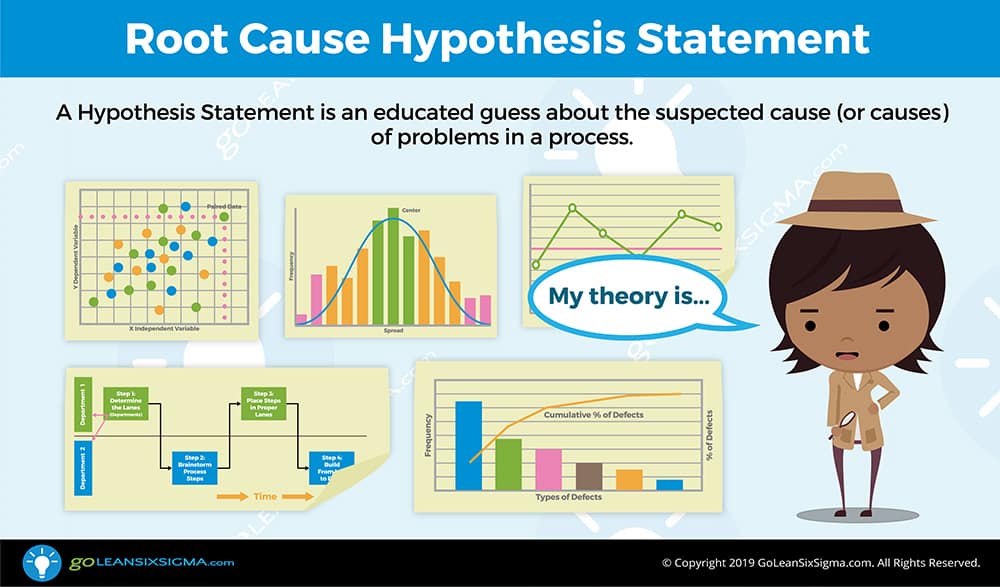

Verify the Cause(s) of the Problem

Before moving on to the Improve Phase the team confirms the proposed root causes by using data, process analysis, process observation and comparative analysis. Verification can be as simple as watching the problem in action or as complex as designing and running hypothesis tests—there are many methods but no one best way.

Tools: Root Cause Hypothesis

Update Your Project Charter

During the Analyze Phase, the team often finds additional detail around process performance and the potential for improvement. The team updates the Project Charter with the new information. By the end of the Analyze Phase, it might be time to bring in new team members.

The uncovered root causes might exist in departments that aren’t represented on the current project team. When that happens, it’s critical to add the right people to the team before moving to the Improve Phase. Don’t make the mistake of fixing someone’s process without involving them!

Tools: Project Charter