Did Taguchi design Kimonos? He could have, if he’d spent his life working in the family Kimono business (and I’m sure they would have been stunning), but lucky for us, this quality rebel devoted a lifetime to the idea that customers deserved better.

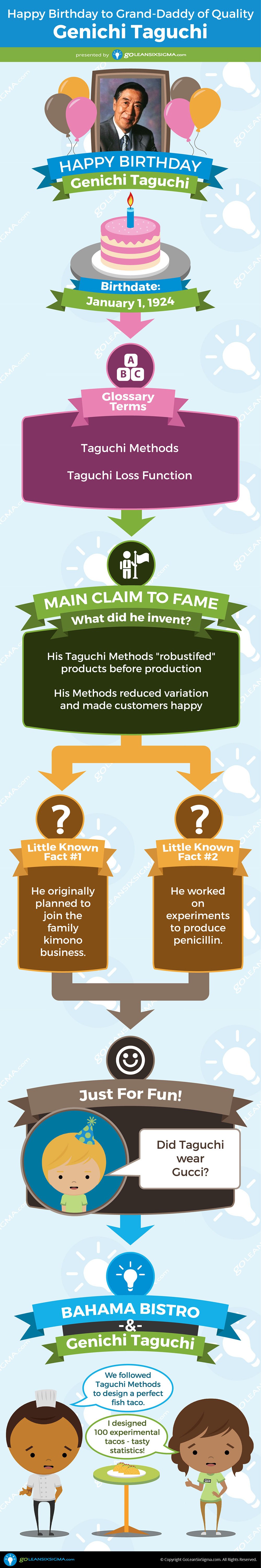

Born in Japan, Mr. Taguchi was an engineer and a statistician known primarily for what’s called the Taguchi Loss Function and the Taguchi Methods. His ideas were applauded by Dr. Edwards Deming but stood in contrast to the theories of Philip Crosby – two notable Grand-Daddies of Quality. His most controversial application was the Taguchi Loss Function.

Claims to Fame – What Did He Invent?

Taguchi Loss Function:

He looked at quality through the eyes of the customer

His idea was that the more products varied from their intended, target state, the more value they lost in the eyes of the customer. Reading that now, it doesn’t sound like a breakthrough idea. But the accepted wisdom at the time was that if a product was outside either the upper or lower specification limit (the “goal posts”) developed internally, then it was defective. Taguchi decided to grade products on a curve (a parabolic curve, if you’re interested) instead of just labeling them “good vs. bad.”

The Taguchi Methods:

His methods “robustified” products before production – he reduced variation and made customers happy!

What’s different about his approach was that he started way upstream at the product design stage. Instead of waiting to measure quality at the end of the production line, he worked with designers and engineers to come up with a product design that was robust enough to withstand mass production. The Methods have three stages:

- System Design – Designing a product that brings value to customers

- Parameter Design – Determining how the product should perform against key measures

- Tolerance Design – Tweaking the design so that it performs well without increasing costs

Little Known Facts:

- He originally planned to join the family kimono business

- He worked on experiments to produce penicillin

Taguchi at the Bahama Bistro:

Quote of the Day:

- “Did Taguchi wear Gucci??”

Putting Taguchi Into Action:

- “We followed Taguchi methods to design a perfect Fish Taco.”

- “I designed 100 experimental tacos – tasty statistics!”

A lot of his work made use of the Design of Experiments (DOE) technique in order to come up with the best combination of factors when planning production (you can see how the Bahama Bistro applies DOE to growing peppers in their Hot Pepper Farm in our Black Belt Training).

His ideas were adopted by Toyota and incorporated into what is now known as Lean Manufacturing. He was an award winning statistician, a long-time professor and a bit of a Quality rebel in his day. We’re lucky to have him in our Quality Family Tree.