Introduction/Overview

Home » Introduction/Overview

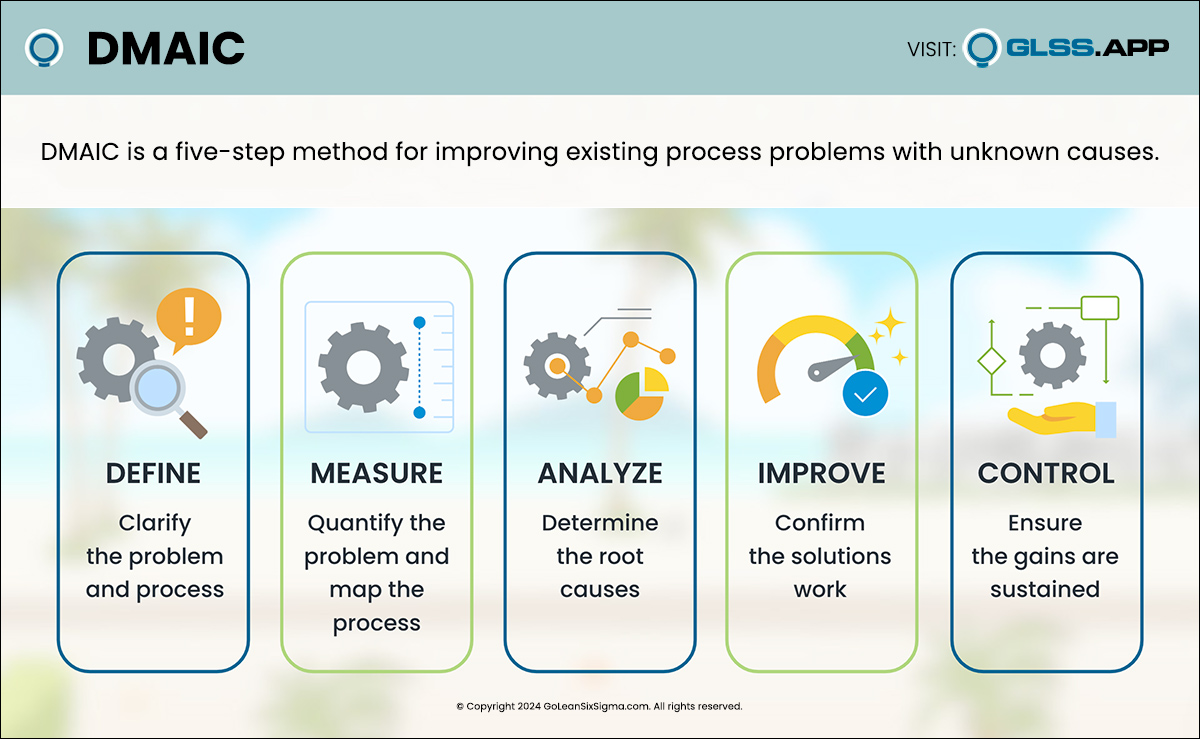

DMAIC is the problem-solving approach that drives Lean Six Sigma. It’s a five-phase method—Define, Measure, Analyze, Improve and Control—for improving existing process problems with unknown

...What’s the secret Quality connection between Italy and Japan? The Pareto Chart! Signore Pareto provided his 80/20 rule and Dr. Ishikawa created the Pareto Chart

...Fishbone + Ishikawa = Fishikawa! We know him best for this essential root cause tool, but did you know Dr. Ishikawa developed the first Kaizens,

...Do you have a hidden factory? Do you know employees who always have time to do it over but never time to get it right?

...Dr. Deming was amazing, but who was his teacher? Who produced the PDCA Cycle? Who conceived of Statistical Process Control? The modest man behind the

...Who is the Grand Poobah of Toyota Production System? The Wizard of Lean? His Royal Eminence of Efficiency? Sure, he had some help, but Taiichi

...What do you know about Sakichi Toyoda? Did you know he was born on Valentine’s Day? That he started out in the textile business? That

...What do you call it when a garage door stops closing before it hits your head? The Hokey Pokey? No, a Poke-yoke! Lucky for us,

...Did Taguchi design Kimonos? He could have, if he’d spent his life working in the family Kimono business (and I’m sure they would have been

...Did you know Dr. Kano was a student of Dr. Ishikawa? Did you know Dr. Kano was still with us? Does he know everyone still

...No post found.