“Don’t rule by fear,” “Stop inspection,” “Remove silos” and “Clarify your purpose.” Dr. Deming’s principles are as applicable today as they were when he was alive. He challenged managers to rule without fear, without targets or quotas and focus instead on setting the stage for pride of workmanship. What workplace wouldn’t benefit today from following Dr. Deming? Time to send up a birthday cheer for this Quality iconoclast!

Dr. Deming is quite possibly the Great Great Grand-Daddy of Quality! It’s hard to sum up as incredible a force in the quality world as W. Edwards Deming. Among other things, he’s credited with helping Japan rise from the devastation of WWII to become the manufacturing juggernaut of the 1970s. His work in Japan caused U.S. business leaders to take note which led Dr. Deming to bring his philosophies and assistance back home. He’s also credited for the rise of the TQM or Total Quality Management movement.

Claims to Fame – What Did He Invent?

The Deming Cycle:

He championed Walter Shewhart’s PDCA

PDCA stands for Plan, Do, Check, Act (or Adjust) which is a process improvement cycle. W. Edwards Deming was mentored by another quality guru, Walter Shewhart during his work at Bell Labs. Dr. Deming was impressed with Mr. Shewhart’s improvement cycle but felt he could make it more accessible. The four Phases are characterized below:

The DMAIC method has come to fill in the “Plan” segment of PDCA with Define, Measure and Analyze, but PDCA is still a great and simple improvement cycle that works well when paired with the A3 for documentation. From his early work with Walter Shewhart where he focused on diagnosing and fixing process problems, he slowly built a larger theory of how to approach organizations as complete “systems.”

System of Profound Knowledge:

He created the System of Profound Knowledge

The System of Profound Knowledge outlines Dr. W. Edwards Deming’s philosophy based on the view that all elements of an organization should work in concert together as an interdependent system. The four elements lay out a framework for managers to reduce costs while increasing quality, customer loyalty, worker satisfaction and, ultimately, profitability. Profitability isn’t last by accident. He firmly believed, and demonstrated, that if organizations focused on optimizing their interdependence first, the money would follow.

Below are the four key parts of the System of Profound Knowledge:

- Appreciation for a System: Understanding the interconnectedness of the all the parts of a system. Process Maps are an excellent way of displaying who does what and how they all connect with each other.

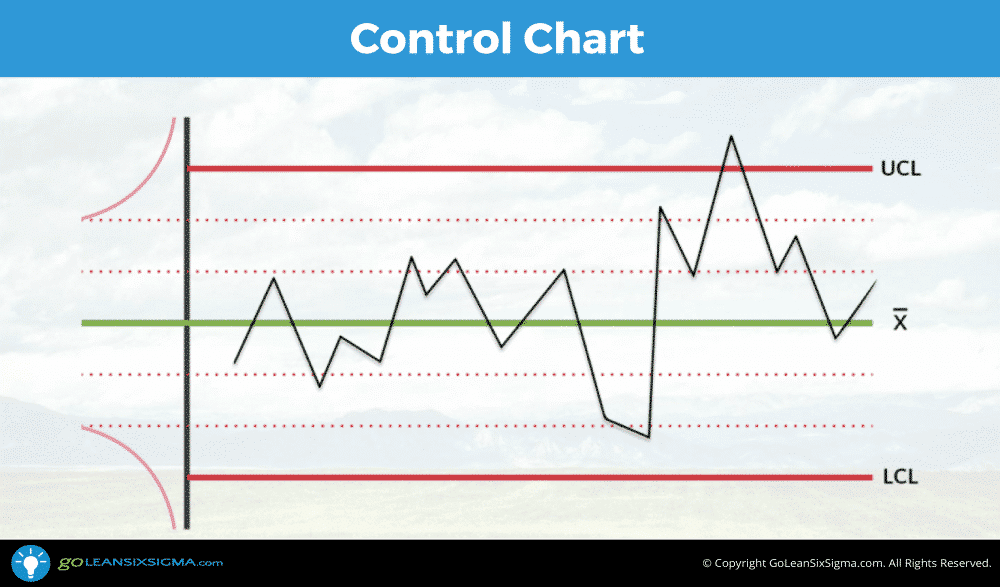

- Knowledge of Variation: Appreciating that no two things are alike and the goal is to reduce the range of variation over time. From his work with Walter Shewhart, he came to appreciate the Control Chart as a way of understanding variation in a process.

- Theory of Knowledge: Understanding the system of improvement depends on continuous study. The Deming, or PDCA cycle provides a system of testing out theories about the system.

- The Psychology of Change: Making sure everyone is aligned around a common purpose, answering the question, “why does this business exist?” and building on this shared identity to build ownership, motivation and joy around collaborating on positive organizational transformation.

In order to help leadership build Systems of Profound Knowledge, he came up with The 14 Points for the Transformation of Management. This was Dr. Deming’s guide for organizational managers to better use their role to improve the effectiveness of the organization. His feeling was that instead of focusing on whether or not workers did as they were told, managers should be using their roles to effect change. These come from Dr. Deming’s book, Out of the Crisis and although much of it is more philosophy than detailed action steps, his goal was to help managers to transform organizations.

The 14 Points for the Transformation of Management:

- Clarify Purpose: Create constancy of purpose toward improvement of product and service, with the aim to become competitive and to stay in business, and to provide jobs.

- Lead the Change: Adopt the new philosophy. We are in a new economic age. Western management must awaken to the challenge, must learn their responsibilities and take on leadership for change

- Stop Inspection: Cease dependence on inspection to achieve quality. Eliminate the need for inspection on a mass basis by building quality into the product in the first place.

- Don’t Focus on Price: End the practice of awarding business on the basis of price tab. Instead, minimize total cost. Move toward a single supplier for any one item, on a long-term relationship of loyalty and trust.

- Pursue Perfection: Improve constantly and forever the system of production and service, to improve quality and productivity and thus constantly decrease costs.

- Train On The Job: Institute training on the job.

- Be Leaders: Institute leadership. The aim of supervision should be to help people and machines and gadgets to do a better job. Supervision of management is in need of overhaul, as well as supervision of production workers.

- Don’t Rule by Fear: Drive out fear, so that everyone may work effectively for the company.

- Remove Silos: Break down barriers between departments. People in research, design, sales and production must work as a team, to foresee problems of production and in use that may be encountered with the product or service.

- Remove Targets: Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the work force.

- Eliminate work standards (quotas) on the factory floor. Substitute leadership

- Eliminate management by objective. Eliminate management by numbers, numerical goals. Substitute leadership

- Allow Pride of Workmanship: Remove barriers that rob people in management and in engineering of their right to pride of workmanship. The responsibility of supervisors must be changed from sheer numbers to quality.

- Abolish Merit Ratings: Remove barriers that rob people in management and engineering of their right to pride of workmanship. This means, inter alia, abolishment of the annual or merit rating and of management by objectives.

- Offer Continuous Education: Institute a vigorous program of education and self-improvement.

- Transform Together: Put everybody in the company to work to accomplish the transformation. The transformation is everybody’s job.

Little Known Facts:

- He played the flute and the drums throughout his life

- The Japanese created the “Deming Prize” to honor his work

Dr. Deming at the Bahama Bistro:

Quote of the Day:

- “I’d rather be riding a Deming Cycle!”

Putting Dr. Deming into Action:

- “The “Plan” is to draw a line on the blender so smoothies are all 12 ounces.”

- “Let’s “Do” it – PDCA!”

Dr. Deming was honored with numerous awards, he wrote cornerstone articles and authored well known books. Those who knew him described him as subtle, funny, generous and very caring, but he was also a hard-working visionary who consulted right up until he passed away at 93 years of age. It took the astounding turn-around of Japanese manufacturing to get the attention of American business. But his teachings are still relevant and he’s quoted daily.