Do you have a hidden factory? Do you know employees who always have time to do it over but never time to get it right? Did you know organizations waste up to 40% of their capacity this way? Well, raise a glass to the quality guru who championed the capture of inspection and rework costs. Lucky for us Dr. Fiegenbaum shared his good work in Japan and here at home!

Often linked with other quality gurus, such as Dr. Deming and Dr. Juran, Dr. Feigenbaum also taught Quality to the Japanese during the 50s. A doctoral graduate of Massachusetts of Technology Institute (MIT) and a winner of many awards and medals, he is known primarily for the concept of Total Quality Control.

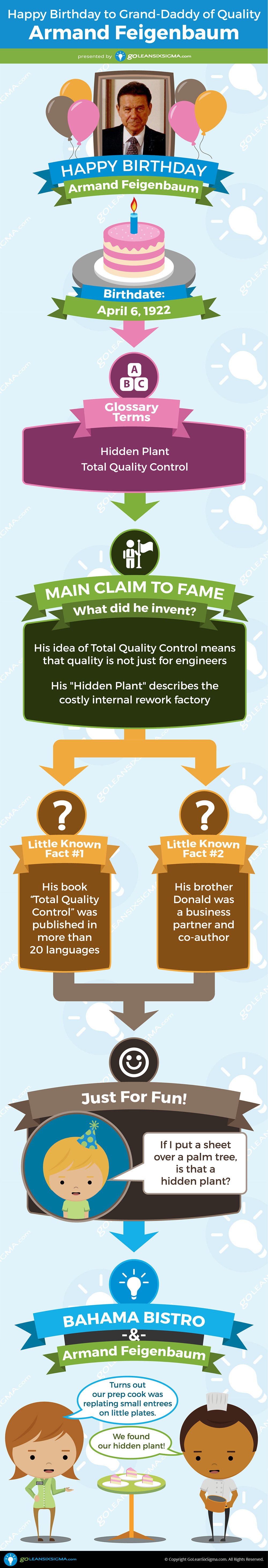

Claims to Fame – What Did He Invent?

Total Quality Control:

His idea of Total Quality Control means that quality is not just for engineers

Dr. Feigenbaum maintained that companies who did well understood that every part of the company has to work in a coordinated way to serve the user. Moreover, that they understood quality is what the customer says it is. He also saw that instead of just making things faster and cheaper, the key to success was making things better. He advised organizations to improve the things they did right and not just cut down the things they did wrong.

Themes of Total Quality:

- The customer defines quality

- It’s important to do things better – not just cheaper and faster

- Quality is everybody’s job; otherwise, it may become nobody’s job

- Leadership has to get out in the field; quality is a full-contact sport

He brought his ideas on Total Quality to companies all over the world. Current efforts in Lean Six Sigma put his idea of “quality is everybody’s job” into practice.

The Hidden Plant:

His “Hidden Plant” describes the costly internal rework factory

The Hidden Plant, or Hidden Factory, referred to the constant rework that goes on inside service and manufacturing firms alike – generally unmeasured. He pointed out that although organizations track returns, scrap and other highly visible costs, they often ignore the wasted labor and other costs resulting from a failure to get it right the first time. He knew, as Dr. Deming pointed out, that a bad process would beat a good person every time.

The Four Categories of Quality Costs:

- Cost of Prevention – mistake-proofing

- Cost of Appraisal – inspection steps

- Cost of Internal Failure – rework loops

- Cost of External Failure – leading to customer returns & dissatisfaction

He pointed out that up to 40% of the capacity of a plant was often being wasted. This shocked a lot of people, but when they actually started measuring the four categories, it was not far off. Dr. Feigenbaum maintained that by investing more in prevention, mistake-proofing and risk management, that failure and eventually inspection costs would go down. Eliminating the Hidden Plan is a way to ensure Total Quality!

Little Known Facts:

- His book Total Quality Control was published in more than 20 languages

- His brother Donald was a business partner and co-author

Armand Feigenbaum at the Bahama Bistro:

Quote of the Day:

- “If I put a sheet over palm tree, is that a hidden plant?”

Putting Armand Feigenbaum into Action:

- “Turns out our prep cook was re-plating small entrees on little plates.”

- “We found our hidden plant!”

Armand Feigenbaum was incredibly generous with his ideas and concepts as he travelled the world helping organizations understand the road to Total Quality. We are indebted to him for quality efforts around the world today.