When customers are satisfied with their first purchase from your company, they patronize you again and your business records higher sales. They tell their families and friends, and they may also choose to buy your products and services.

That first experience with your product and your service matters. Customer satisfaction builds customer loyalty. If they recommend you, that results in a better partnership. Customer retention builds the brand, increases sales and leads to employee happiness.

What Leads to Great Products and Services?

According to Quartz, 20 years ago, no company topped the industry more than General Electric. Even in the early 2000s, GE surpassed Microsoft to become the world’s most valuable company. How did they achieve this feat? They implemented Six Sigma.

With it, the company was able to reduce many key processes to 3.4 defects per million opportunities. They strove for 99.99966% quality with their products and services—almost zero flaws.

The Master of Project publication states that Motorola, one of the first companies to implement Six Sigma, saved $17 billion. They most famously applied it to their pager production, but they also applied it to sales and marketing, customer service, product design, and processes all across the business.

Lean Six Sigma and business processes are interwoven. And this is exactly what I’ll be covering in this article.

Also, I’ll outline the steps you can take to prepare any process for improvement. Let’s get started with some facts about the Lean Six Sigma.

Facts About Lean Six Sigma

It is important to understand some basic Lean Six Sigma terminology and how it makes it easy for your business to achieve quality management, improve organizational processes, and achieve overall success—just like Motorola and General Electric.

Fact #1: Lean Six Sigma is a Combination of Two Methodologies

The approaches of Lean and Six Sigma have different origins, yet they have similar goals. Six Sigma originated at Motorola back in the 1980s and Lean Originated at Motorola back in the 1940s.

They both aim to reduce waste, increase customer satisfaction, and increase revenue. They both follow the Scientific Method. They both target the building of value for the customer experience, and they employ process mapping to approach and understand processes.

Fact #2: Lean Six Sigma is a Business Methodology

Lean Six Sigma depends on the collaborative effort of teams whose aim is to improve performance by tactically removing waste and reducing variation.

It is a methodology that not only works in manufacturing, as many people assume, but also works in the service world. In fact, it’s being used in transactional processes as much if not more than in manufacturing. It has been tested in the healthcare industry, government, the nonprofit world—every industry—and has proven to be effective.

It promotes a certain mindset that pushes employees and managers to focus on growth, establishing best practices and the continued optimization of processes.

Fact #3: Lean Six Sigma is a Learning Process

The Lean Six Sigma methodology is not a one-off activity.

The point is to use it—evaluate the results—make adjustments—and use it again. Analysis and change are key. That’s how companies produce excellent results. The methodology leads users on a pursuit of perfection. Processes improve, but they can alway be better.

Fact #4: Lean Six Sigma is a Set of Tools

The underlying structure of Lean Six Sigma involves the wealth of tools that can be used in processes. These are the tools that help teams eliminate defects and errors as they pursue their goals.

These tools are centered on productivity and business process management.

Sample tools and concepts include: Brainstorming, Value Stream Mapping, Kaizen, Just-In-Time, Single Minute Exchange of Die (SMED), Jidoka, Gemba, Pareto Charts, 5S, etc.

Fact #5: Lean Six Sigma is a Project-Based Approach

Organizations realize the power of Lean Six Sigma through the success of each project.

When a problem arises in any sector or department where the Lean Six Sigma approach is adopted, employees or leaders qualify the problem, assign a team and start the cycle of improvement. Projects can bubble up from the front line or come down from upper levels of management.

The culture of improvement puts every cross-functional team on their toes, striving for perfection, working on solutions as they define new best practices.

Lean Six Sigma and Processes: They Go Hand-in-Hand

In order to find the bottlenecks in the process, it’s critical to map it, measure it and evaluate it. By understanding the flow—or lack of flow—it becomes possible to update and refine the Standard Work and best practices.

After mapping and understanding their processes, companies can understand where to channel their transformation energy and, by doing so, improve their processes across the board. Process flow mapping is integral to understanding processes.

Organizations conduct data collection and use it to understand how efficiently they use their resources to produce their products and services. The data, combined with process maps, helps them understand what can be improved about the creation and distribution of the products and services.

Lean Six Sigma relies on data to determine the current performance of processes and to understand the root causes of bottlenecks and other process issues. Lean Six Sigma and business process management go hand in hand within three broad criteria:

- Process and Methods

- Tools and Techniques

- Mindset and Culture

Process and Methodology

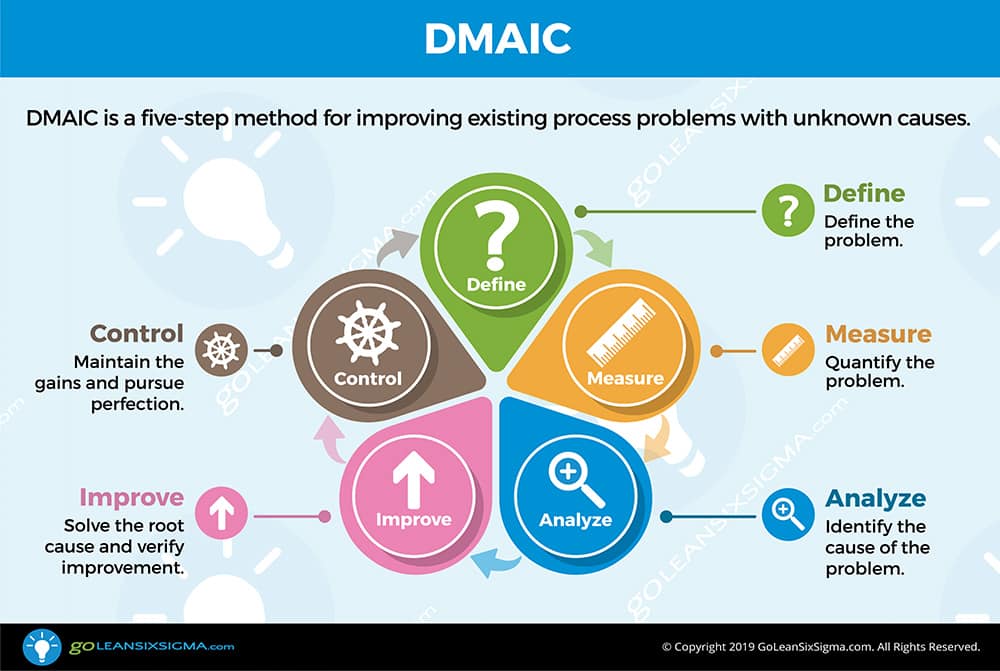

This aspect involves the phases that provide structure for the problem-solving tools. The classic process used is called DMAIC: Define, Measure, Analyze, Improve and Control. The DMAIC process outlines how to utilize tools and concepts to ensure that the root causes of process issues are identified, verified and addressed.

Process goes from problem identification, mapping of processes, through to implementation of targeted solutions. I’ll cover DMAIC in more detail, but below is a high-level outline.

Tools and Techniques

This aspect refers to the toolsets, strategies, and analytical techniques that have been tested for decades in the quality world. These have been refined to work in disparate industries, across all types of processes in the physical as well as the digital realm.

Mindset and Culture

This aspect centers around how the company’s decision-makers perceive or think about using data to make decisions. It’s important for everyone in the company to align around the same fact-based method. It’s key that process work revolves around using the same system to achieve operational excellence.

In order for this to work, it’s key to promote a blame-free environment. Employees must be encouraged to point out problems. In order to continuously improve, the organization must build a problem-solving culture.

In order to stay consistent, and support new hires, it’s good to have standard practices for new hires. One common process to address is onboarding. A great place to start is to create an onboarding checklist for new employees.

How the Model Interacts

The Process, the Tools and the Culture must mutually support each other. For instance, the analytical techniques will not be useful unless everyone is applying DMAIC the same way and the organization has a mindset and culture of continuous improvement.

The improvement will fail to generate the desired results without the effective use of the right tools and techniques to guide the improvement activity. The culture must insist on a data-centric approach to solving problems.

The Common Wastes That Could Slow Down Processes

Lean Six Sigma is unique because of its ability to eliminate waste. Waste, in this methodology, has specific definitions. Below are the 8 Wastes that could slow a process down and block the flow. When they do, organizations waste time and effort. What’s key is to identify and remove waste from the system.

Defects

In the course of completing a task, if you go back to fix an error, you waste time. The goal is to complete tasks accurately on the first try.

Overproduction

Producing more than the needed amount of products or services is a waste. When you overproduce, you need a place to store materials.

All the resources put into storing and ensuring that products and materials are accessible can lead to waste. The waste increases if the product doesn’t sell on time. The key is to determine the right amounts to produce to meet customer demand.

Waiting

Waiting is waste in business. As the adage goes, time is money. You pay your staff based on their time so when they’re idle, the company loses. And the customer loses when products and services are idle.

This could happen as a result of unbalanced workloads, staff waiting for instructions, close-marked supervision, or poorly designed work processes. Regardless of the cause, the goal is to reduce delays.

Non-Utilized Talent

Employees with unused skills, or employees not being tapped to the full extent of their abilities is a common loss for business. It’s a waste of talent and it leads to employee boredom and lack of engagement. This waste goes unnoticed but it can benefit both the organization and the staff when it’s recognized. Employees want to contribute and feel useful.

Transport

Moving products from one point of service to another is considered waste. If it’s not adding value, moving things around is wasteful.

As an example, an auto sales representative might mistakenly pick the wrong delivery and then return it to the warehouse.

From the space the goods occupied to the time and effort invested in carrying the product—all are considered waste. The more products and inventory are moved, the more the chance for damage or injury.

Inventory

Though some inventory is necessary to manage shortages. If it’s more than customer demand requires, it does not add value. Inventory occupies space, financial resources, and as it ages, it could diminish the quality of your product.

Movement

Any unnecessary movement of man (staff), machine, or material is a waste of time. This includes ergonomic-based movements, like unnecessary bending, lifting, reaching, walking, turning, or kneeling. It also includes opening multiple apps and clicking through tasks unnecessarily.

The key is to study, assess and remove unneeded human movement.

Extra-Processing

This is the waste that includes unnecessary inspections and approvals. When processes go unchecked, they grow in size and complexity. When things go wrong, people insert inspections and approvals instead of developing a mistake-proof process.

Employees tasked with endless reviews are not able to add value. Extra-Processing takes time and generally adds nothing to products and services.

Using DMAIC for Process Improvement

The aim of the improvement in a process is to reduce waste and variation that emerge in processes over time. Paying attention to these issues helps the company avoid losing time and money. The goal is to eliminate wasted process capacity and activities that lead to variation.

As described absolve, the process improvement method used within Lean Six Sigma is the 5-step DMAIC Method. The steps are outlined in more detail below.

Define

During this phase, you define the problem, state the goals and outline the boundaries of the project. A team comes together and agrees on their roles and the high-level plan.

During the Define Phase, the process is mapped, the team works to understand what the customer expects of the process, and what the desired process performance should be.

Understanding the Voice of the Customer is key to ensure that changing the process improves the customer experience.

Measure

This is where the team puts a number to the problem.

They gather information about the current situation, obtain baseline data on current process performance, and identify potential problem areas.

Having a baseline enables the team to ascertain if there’s difference once they implement the solution. They need to establish the gap in order to measure the improvement against the baseline when they get to the Improve Phase.

Analyze

The next step is to analyze the process and the data about the project or service to identify the root cause of the problem. Once identified, the team can channel their efforts. There’s usually more than one “smoking gun” so the team spends time here to capture the right issues.

It’s key to verify the root causes and not go with hunches. This takes time and effort and there could be pressure to jump to a solution without verification. The root cause must be real and backed up by data—not a mirage.

Improve

This is where the change takes place.

In this phase, you implement solutions that directly address the root causes of the process problems that were confirmed with data during the analysis stage.

The key is to assess each potential process change for the effort it will take to implement and the impact it will have on solving the problem. This phase involves piloting and testing countermeasures to refine and adjust until they work. Once they’re final, then it’s time to label them”solutions.”

The solution has to have the desired effect—variation and defects must be reduced or eliminated.

Comparing the new process capability to the baseline—and closing the gap—concludes the phase and sets the process up for continued success.

Control

There is no use improving a system if you’re not prepared to maintain the gains. And that means you’ve got to evaluate and monitor the performance.

Once the changes have been implemented and the other associated systems have been updated, the entire process, product, or service should be closely monitored. The classic term for this is statistical process control.

This ensures that the solution is sustainable and that everyone knows what to do if there’s a dip in performance.

Conclusion

The Lean Six Sigma methodology strengthens organizations and improves their business process capabilities such that they raise employee morale, produce more quality products and services, and rake in more profits.

But you’ve got to do it right.

If you don’t want your organization to fall behind then it’s time to prepare for process for improvement.

Ready to improve your company’s business process? Click here to sign up for a 28-day free trial of SweetProcess; the software that helps you to document your processes, procedures, and tasks.