Who put the “Six” in Six Sigma? Who’s the man behind the first Malcolm Baldrige Award and how did he get so good at betting on race horses?

Mr. Smith is credited with coining the term “Six Sigma” and developing the signature process improvement method while serving as Vice President and Senior Quality Assurance manager for the Land Mobile Products Sector of Motorola in 1986. Within 2 years of the introduction of Six Sigma, Motorola reduced pager defects to less than 3.4 per million opportunities and had won the Malcolm Baldrige National Quality Award. Within a decade they had achieved a five-fold growth in sales, with profits climbing nearly 20 percent per year.

Claims to Fame – What Did He Invent?

Six Sigma:

His Six Sigma concept standardized the way defects were counted.

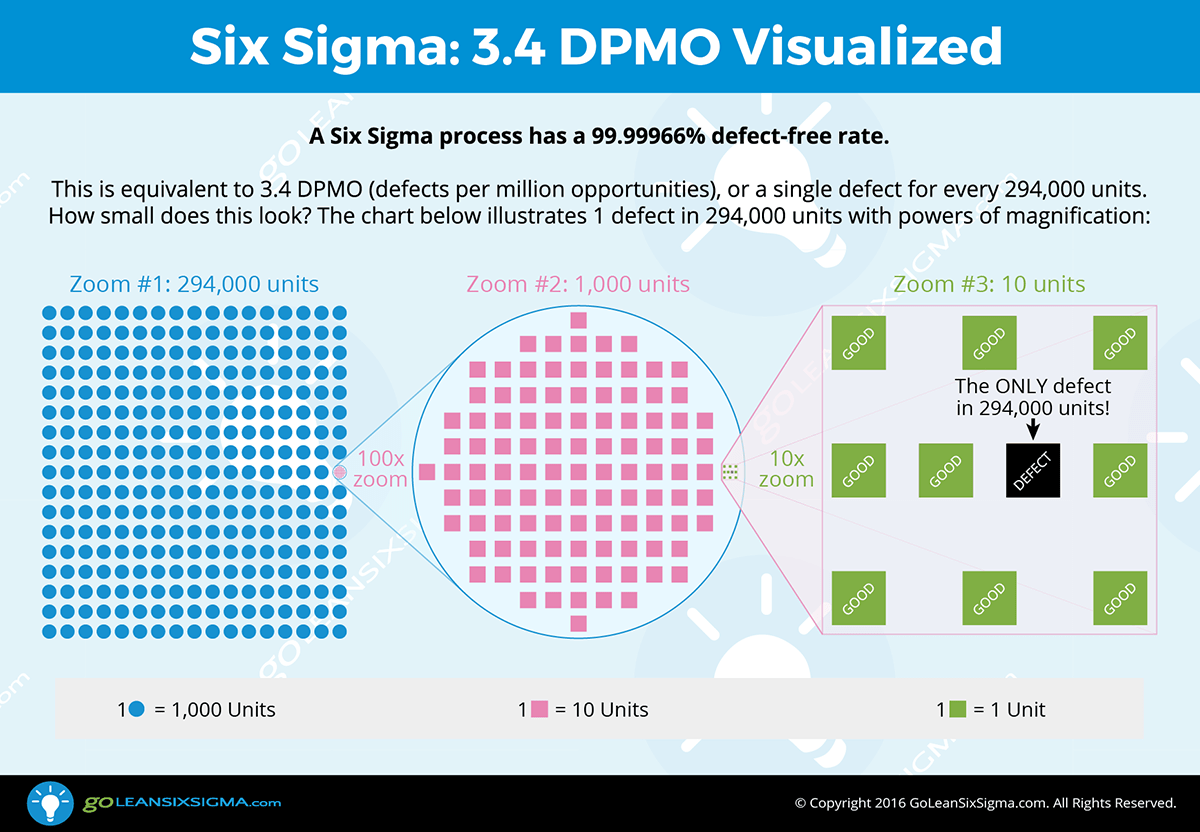

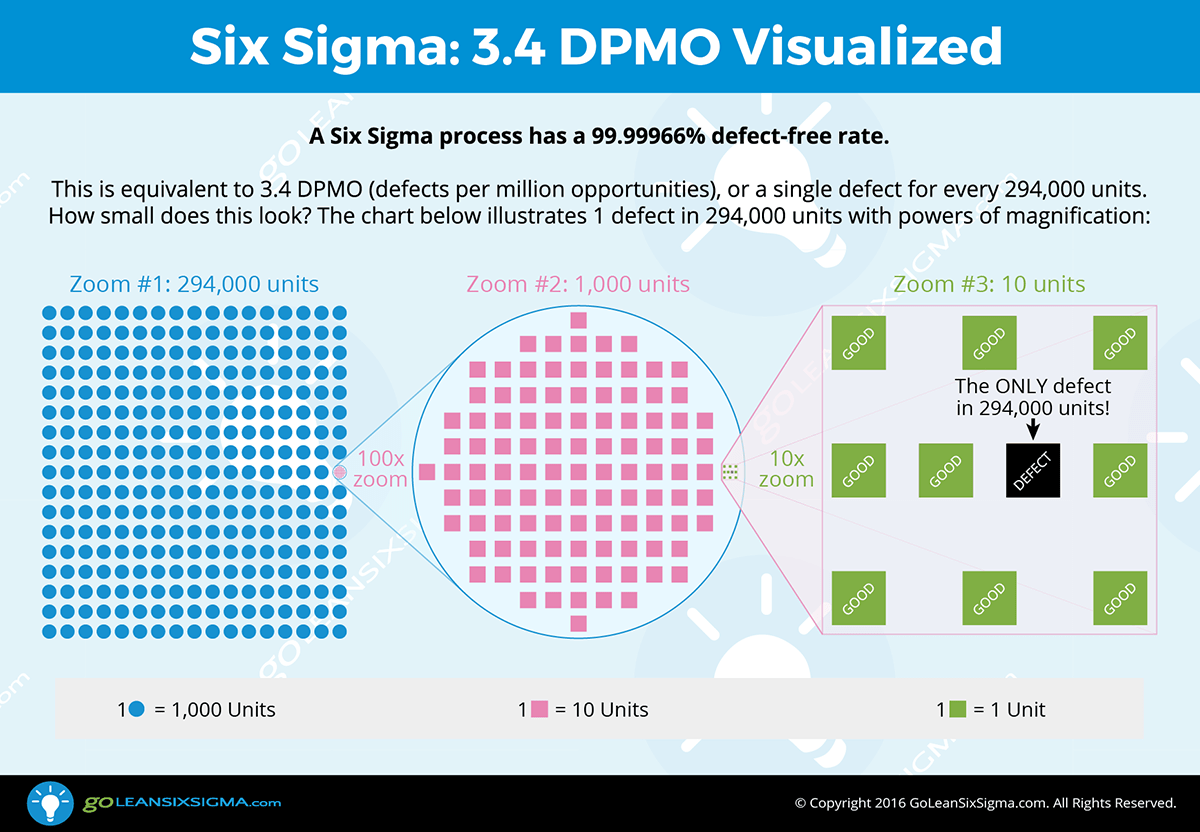

Mr. Smith built on the concepts of the 19th century mathematician Carl Friedrich Gauss along with fellow Grand-Daddy of Quality Walter Shewhart to introduce a more exacting method of counting defects. Instead of measuring the number of defects per thousand opportunities, Mr. Smith thought Motorola should hold itself to a higher standard. He recommended setting the goal at just 3.4 defects per million opportunities. This meant a quality level of 99.9997%. He reached this “close to perfection” number based on the normal or “bell curve” distribution of process data.

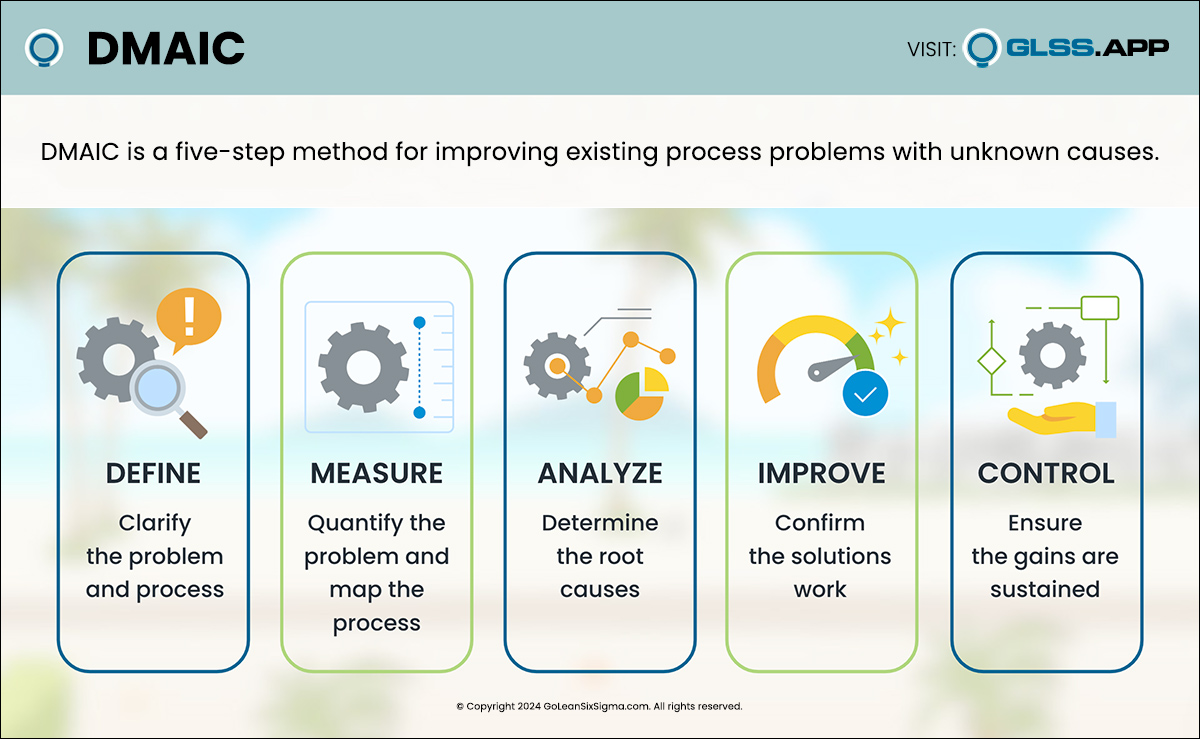

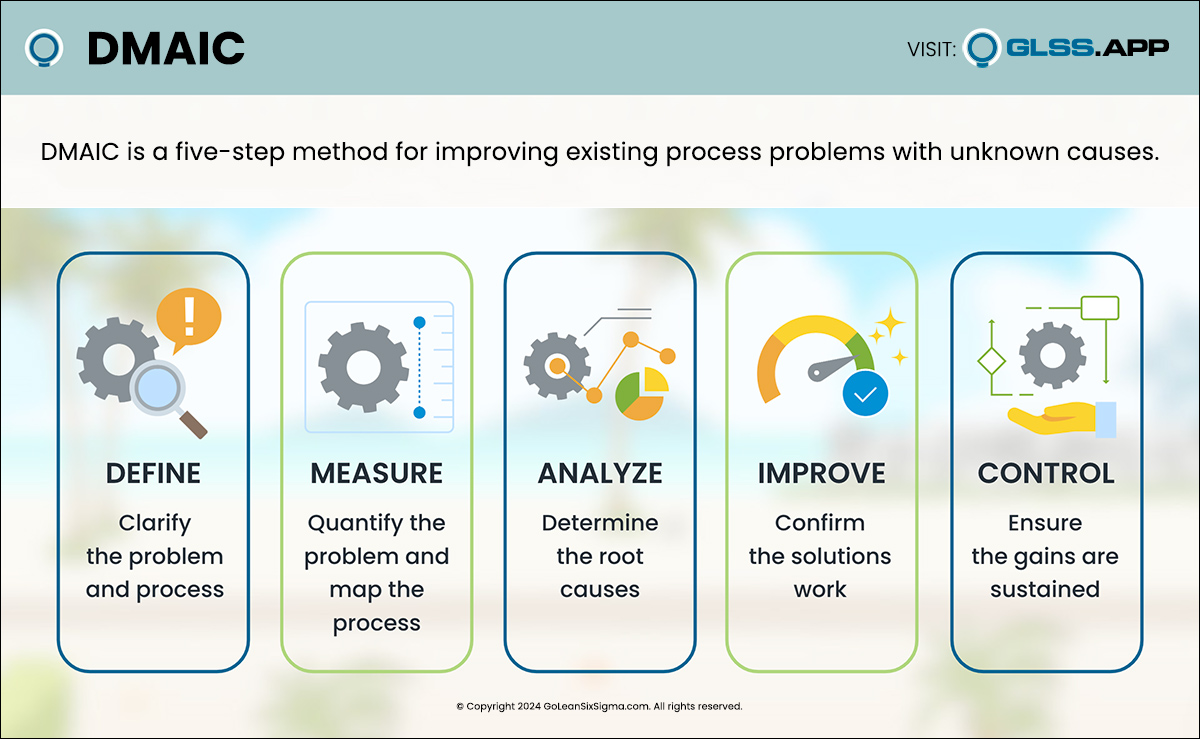

The improvement process he developed was a TQM spin-off but his goal was establishing it as a way of doing business. Initially the method designed to reach the goal of Six Sigma was defined as MAIC or Measure, Analyze, Improve and Control. This eventually expanded to include the Define Phase resulting in the DMAIC method Six Sigma is known for today. Thus, Six Sigma is a goal, a method and it’s also a philosophy for managing process improvement.

Malcolm Baldrige Award:

Winning the Malcolm Baldrige Award spread Six Sigma worldwide.

If Motorola had been quiet about their accomplishments, the world may never have heard about Six Sigma. Winning the award changed the game since Baldrige Award winners agree to share their quality programs with anyone who is interested. Due to Motorola’s stellar business success, a lot of companies were interested in Six Sigma. This method quickly spread to other organizations and GE, in particular, achieved significant and very public success. Under Jack Welch, Six Sigma is credited with saving $10 billion. Bill Smith passed away too young to see the amazing impact of his ideas, but this method has spread to tens of thousands of companies all over the world and is alive and well over 30 years later!

Little Known Facts:

- He owned a stable of profitable racing horses

- He played the organ and his wife played piano with him at home

Bill Smith at the Bahama Bistro:

Quote of the Day:

- “I want the Baldrige Award for our Bahama Mama Smoothies!”

Putting Bill Smith into Action:

- “Are you making cheeseburgers?”

- “No – I’m making Six Sigma Burgers!”

Bill Smith is often linked with Mikel Harry since together they worked to develop the Six Sigma method and the training needed to spread it to employees. Six Sigma has since been aligned with Lean methods and the combination is referred to as Lean Six Sigma. Shortly after his death, Kellogg Graduate School of Management at Northwestern University established an endowed scholarship in his name. Mr. Smith received an induction into the Six Sigma Hall of Fame posthumously in 2011. His daughter Marjorie Hook, another Six Sigma devotee, received his award. Bill Smith was known for being a great communicator, sharing his depth of knowledge with those around him and reveling in their success. A lovely legacy.