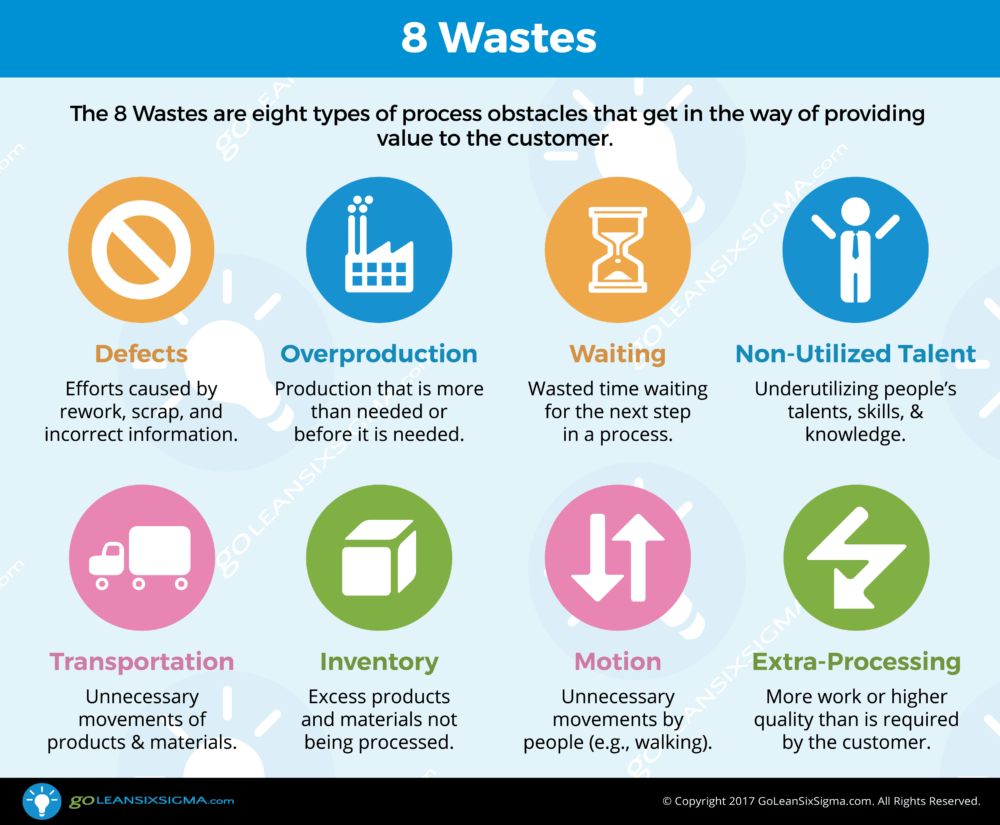

The 8 Wastes refer to a list of issues that get in the way of process flow and cause stagnation. The list consists of Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing. The idea of process improvement is to identify and remove all forms of waste from a process in order to increase efficiency, reduce cost and provide customer value.

8 Wastes Training Single Module

For a better understanding of the 8 Wastes and an overview of Lean Six Sigma, check out our 8 Wastes Training!