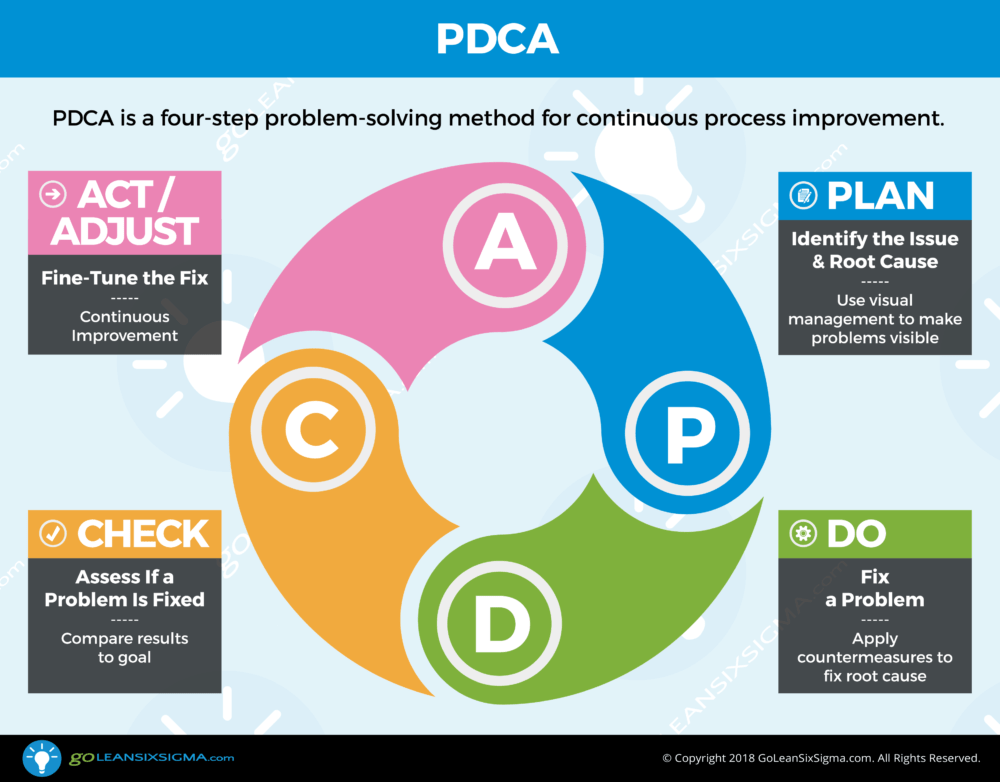

PDCA is a four-step methodology for problem-solving. PDCA stands for Plan Do Check Act/Adjust. It can also stand for Plan Do Study Act. This methodology can be used continually to improve processes.

Plan: Plan or outline a problem.

Do: Do or apply countermeasure to address root cause.

Check: Check or assess if the problem is fixed.

Adjust: Adjust or fine tune the fix.

PDCA is a method developed by Dr. Deming that favors trial and error over extensive planning and trying for perfection up front with the assumption the each test allows for essential fine tuning. PDCA is often paired with A3 Documentation.