What is 5S?

5S In-Depth

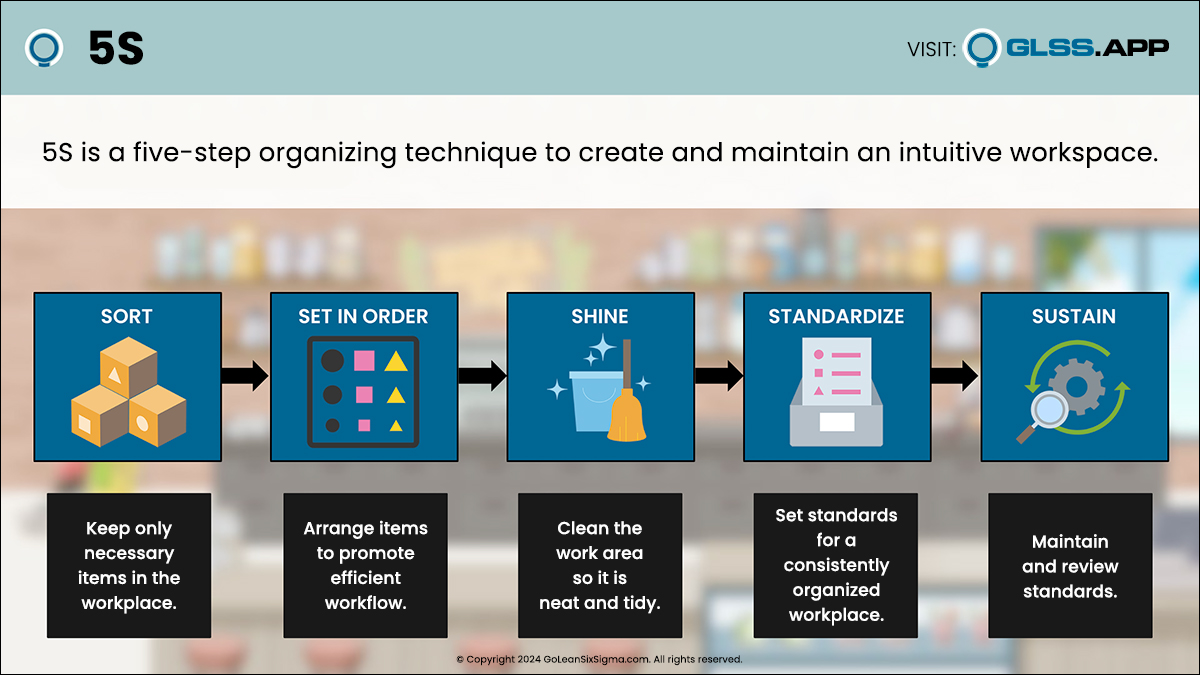

5S is a five-step organization technique to create and maintain an intuitive workspace.

Sort – Keep only necessary items in the workplace.

- Review tools, parts, and instructions.

- Keep only what is essential

- Eliminate anything that is non-essential.

Examples: Obsolete/expired procedures, damaged/expired inventory, defunct/old equipment

Set In Order – Arrange items to promote efficient work flow.

- Arrange items in a logical order.

- Indicate places for each item clearly.

- Keep each item close to where it will be used.

Reduces: excess movement, excess transportation, over processing, over production, excess inventory, excess delays, defects

Shine – Clean the work area so it is neat and tidy.

- Make cleaning a part of daily work.

- Assign areas of responsibility.

- Return all items or files to their assigned place.

Examples: Dirty tools & equipment, spills & leaks, clutter & mess

Standardize – Set standards for a consistently organized workplace.

- Create standards for Sort, Set In Order, and Shine.

- Make standards easy to understand with Visual Controls.

- Assign and educate on individual responsibilities.

Examples: Work instructions, hazard warnings, equipment/tool labels, process diagrams

Sustain – Maintain and review standards.

- Measure and monitor process.

- Address root causes and avoid reversion to the “old ways.”

- Promote individual feedback and response for improvements.

Examples: Emphasize cooperation, communicate clearly, and support innovation.

To learn more about 5S, check out our Yellow Belt Training & Certification!

Or automate your Lean Six Sigma projects with AI using Kure.