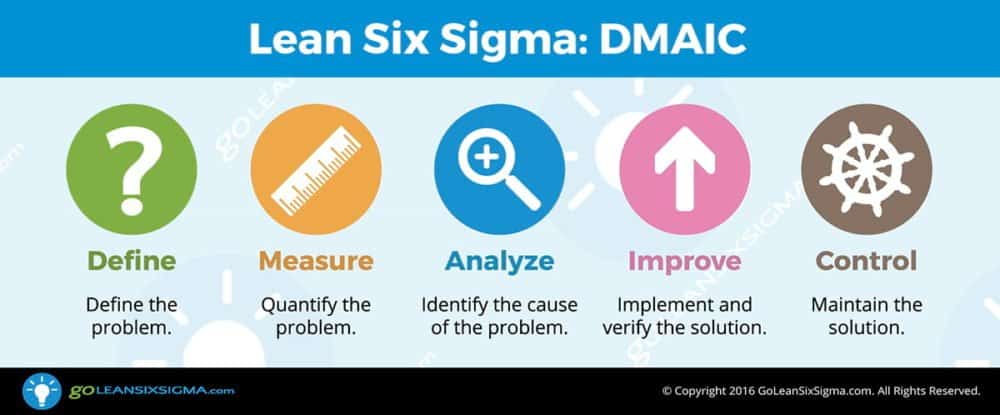

I find that in business and personal life problem solving techniques are a great asset. GoLeanSixSigma.com introduced me to the DMAIC approach to problem solving and here is a fun application where it produced a sweet result.

The wonderful colours of fall in the Northeast have arrived and here in Canada as we celebrate Thanksgiving (it’s in October in Canada) at the cottage in the splendor of the red maple tree.

The maple tree is important to Canada not only as the symbol on our flag but also for its economic value – as a source of hardwood lumber as well as the unique result of its sap, maple syrup.

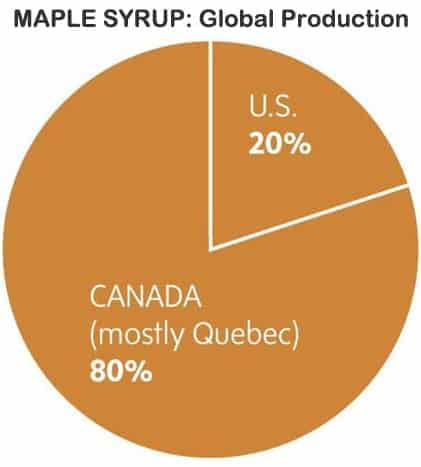

Maple syrup production, along with raising great hockey players, is a uniquely Canadian skill – we produce 80% of the world’s supply. Our US neighbours, primarily Vermonters and New Yorkers, produce most of the remaining 20%.

Maple syrup production, along with raising great hockey players, is a uniquely Canadian skill – we produce 80% of the world’s supply.

There are around 16,000 maple syrup producers in North America and about half of these are in the province of Quebec where it has developed into an important export industry. There are hundreds of small operators producing syrup for family and friends but the majority of syrup exported around the world comes from large commercial tree farms where they harvest sap from thousands of trees each year.

Last year, Canada produced about 12 million gallons of maple syrup – 70% from Quebec. Global exports of maple syrup in 2016 were valued at $350 million – Canada accounted for 81%, the US for 8% and surprisingly another 6 European countries including Germany, France and Ireland also exported syrup.

How Is Maple Syrup Made?

Maple syrup has a long history as it was known and valued by the indigenous peoples of eastern North America long before the arrival of European settlers. The Iroquois pierced the bark and used the “sweet water” to cook venison. Today we have maple-cured meats. The Ojibwa called the “sugaring off” period the Maple Moon or Sugar Month.

The process of creating maple syrup – as a natural sweetener containing the essential trace minerals potassium, magnesium phosphorous, iron, zinc, copper and calcium – begins in the fall when the trees store complex sugars in their base.

Sap flow starts in the spring when daytime temperatures are above freezing while nights drop below. Positive pressure and a pumping action in the tree provides sap flow from a small hole bored into the trunk through an inserted spigot into a collection bucket. The collection process doesn’t harm the trees since it takes only about 7% of the tree’s sap and the holes heal over the following summer.

Some sugar maple trees in Quebec and Ontario are over 100 years old. A typical tree produces about 10 gallons of sap per year during the 6 to 8 week window when the sap flows.

Predicting exactly when the sap will flow is a tricky aspect of the production process since it is weather dependent. Processors remove the excess water from the sap, filter and boil it to sterilize it and achieve the correct sugar content. Many producers still use traditional wood fired evaporators to remove the water while others use a combination of reverse osmosis and various fuels for the boiling process.

Lean Six Sigma and Maple Syrup?

I expect that by now you are thinking, “interesting information about maple syrup and sounds like a lot of fun for the family… but what does this have to do with Lean Six Sigma?”

Our family’s adventure as a small producer best illustrates the alternative facts about this back-to-nature, quaint hobby industry that should send any reasonable person running to the local grocery store to quench their desire for maple syrup. Fortunately, applying the basic principles of Lean Six Sigma probably rescued our family enterprise for a few more years and tipped the scale of pain versus enjoyment in favour of the latter.

The truth about maple syrup production is that on a small scale it is extremely physically taxing and potentially very expensive!

Fortunately, applying the basic principles of Lean Six Sigma probably rescued our family enterprise for a few more years and tipped the scale of pain versus enjoyment in favour of the latter.

Growing Pains

Our enterprise started a few years ago when a couple of young nephews decided to make their own syrup. They purchased some basic equipment on Amazon and proceeded to drill holes in half a dozen trees – mostly on my property. When a little sap showed up in their buckets they built wood fires, balanced a couple of old pots over the flames and then spilled most of it but produced enough to get a taste.

Over the next couple of years, while I was away working in the U.S., they expanded their operation to a dozen trees and enough syrup to enjoy on pancakes at summer cottage breakfast. Sounds harmless! But the truth is their parents subsidized the production process by supplying massive amounts of propane to boil away the water.

Did I mention that it takes 40 gallons of sap to produce 1 gallon of syrup? That is a horrible ratio and boiling can’t be done inside because the vapours would deposit sticky water all over the walls. Beyond that, the trees were scattered across many acres which meant we had to haul 40 gallons – of essentially water with a tiny amount of sugar – from each tree to the central processing point.

Slogging gallons of water across snow-covered, slippery hills is a recipe for muscle strains and twisted ankles. There is no joy in the physical labour of maple syrup production.

The resulting syrup cost us around $40 per liter while we could purchase the same quality product for around $15 – quite a price to pay for the privilege of homemade syrup.

The resulting syrup cost us around $40 per liter while we could purchase the same quality product for around $15 – quite a price to pay for the privilege of homemade syrup.

Solving Our Syrup Problem With a Sweet Solution

On my return to Canada my nephews and their parents asked me to get involved in the maple syrup project (as a CPA and engineer) to see if I could find a way to reduce cost and labour, or perhaps cancel the project since they were mostly my trees. I immediately thought of my friends at GoLeanSixSigma.com and the DMAIC approach to problem solving.

Define Phase

Defining the problem required that I listen to the customers; my nephews and their cousins wanted to continue the experience of home-produced quality maple syrup, and the stakeholders, my in-laws (parents of nephews and nieces) did not want to pay double or triple for the home-produced privilege. The problem had two components – the volume and therefore the cost of propane required to boil away water and secondarily the labour required to move sap.

Measure Phase

Measuring the size of the problem was a little difficult as I was not present for the prior year’s event, but certainly the multiple tanks of propane used were well beyond reasonable for the output.

Analyze Phase

Analysis of the process used in the past confirmed, once again, that labour was excessive and, while that was free, patience was wearing thin. The bigger issue remained the cost of propane. Additionally, following this process contributed negatively to the environment with high carbon emissions and a lot of wasted energy.

All of us at our family cottage compound try to minimize our environmental impact so this was a big factor. We decided to look to the professional enterprises which tap as many as 2,000 trees with the thought that their processes might provide helpful hints.

There are many operators who still use wood-fired evaporators which unfortunately are significant air polluters since wood fuel is seldom more than 75% efficient. Others use natural gas or propane but as they operate on a larger scale they can invest in and effectively operate large evaporators with heat recovery systems.

Reverse osmosis (RO) has gradually gained favorability in the food industry in various applications including maple syrup production. RO is a water purification technology that uses semi permeable membranes to remove ions, molecules and larger particles. Pressure applied by water pumps overcomes the natural osmotic pressure in a solvent to separate solvent from dissolved particles. It is used to purify water and to concentrate orange or tomato juice. RO systems, however, are quite expensive – typically $10,000 to $20,000 and they are fairly complex. Not a viable solution for my nephews but many large maple syrup operations are adopting this technology.

Not willing to give up on the “technology” solution so easily, I continued my research and, through maple syrup blogs, discovered a few small producers who had cobbled together “homemade RO systems.” Digging deeper I uncovered a set of diagrams describing a system assembled from household water filtration components that appeared to be constructed for a couple hundred dollars.

With additional research we found components at excellent prices from a water filtration component warehouse in Toronto and we found other parts on Amazon. The key to this low-cost tech was to run the household RO system in reverse to remove water from sap. In order to do this we had to keep and further concentrate the liquids that in typical water filtration systems are considered the waste and then discard the purified water.

For anyone with a chemistry or engineering background this is a great Eureka moment. Suddenly it all seemed so simple and economical; repurpose existing technology in a unique way – “Reversed Reverse Osmosis!!” Assembling the RO system; with a pump, large particle filter, pressure gauge, three stages of RO membranes and a needle valve was quite simple.

Improve Phase

I reached the Improve stage of DMAIC with a technology solution, with fingers crossed that it would work as designed. I am a huge believer in technology solutions. I believe we can make great improvements to business and society by taking advantage of existing technology and by inventing new ones. A relatively simple industry like maple syrup production can in fact be a disproportionately large source of pollution and an energy hog when using the old technology of wood burning evaporators.

Spring arrived quickly in 2017 with a heat wave in February. The sap started running in early March which is much earlier than normal. Fortunately we tapped our trees earlier this year and were therefore able to collect lots of sap.

We made a few minor adjustments to our process such as running the lines through a bucket of warm water to speed up the sap flow through the RO membranes, and we had immediate success – pure water (99.99%) was rejected and the concentrated sugar water was saved. We were able to remove around 75% of the water by recirculating the concentrate back into the beginning of the concentrator, a neat little trick.

We still had to boil the final sugar water product to sterilize it and increase the sugar concentration to produce a syrup, but we saved tremendous amounts of propane and reduced the manual labour at the evaporation stage.

We saved a lot of our energy for the manual job of hauling watery sap from the dispersed trees to our central processing location. A tougher job this year because of the amount of snow and ice still on the ground. Our next opportunity is to reduce wasted labour or inefficiencies, but that will have to wait for the next season.

Control Phase

The final stage of DMAIC is Control. Here we didn’t have much of a problem maintaining the solution as the alternative of going back to boiling the sap from the onset no longer made any sense. Everyone was happy to stop the wasteful and labour-intensive steps of the past. An interesting point to remember for many business problems: a new process that is far superior to the old way of doing things ensures that everyone works hard to maintain the process during the Control Phase.

Sweet Satisfaction

Maple syrup season came and went very fast and we produced about 25 litres of syrup. Enough for friends and family to get a taste of the sweet homemade solution.

In summary, using the DMAIC approach we quickly defined and measured the problem, we spent considerable time analyzing and looking for a unique and creative solution and, once we found a technology at a reasonable price, we implemented the improvement and maintained control as the new process was fun, educational and labour saving.

Thanks to GoLeanSixSigma.com and DMAIC! Enjoy your pancakes with Canadian Maple Syrup.

P.S. You may be amazed to hear that Canada maintains a strategic reserve of maple syrup (similar concept to the US reserve of oil or helium), to manage supply which is currently at 46 million pounds. In 2012 three employees and five accomplices were arrested for stealing $18 million worth of maple syrup (6 million pounds) which they replaced it with water. The maple syrup gang is currently serving time, I guess they should have been prepared to take the bitter with the sweet!