Hospital Reduces Motion In The Pulmonary Function Lab By 85% With GLSS

Home » Case Study » Hospital Reduces Motion In The Pulmonary Function Lab By 85% With GLSS

Illinois

Healthcare

Patient Care

85%

PROJECT SUMMARY

- Problem: A Pulmonary Function Testing (PFT) lab, which checks how well a patient’s lungs are working, found that its staff needed to move around too much to provide patient care. They also noticed a lot of disorganization in their department. This made it harder to give care quickly and made the staff seem disorganized and unprofessional.

- Root Causes Discovered:

- Searching several locations to find needed supplies

- Staff often retraced steps

- Disorganization and waste within the department

- Long distances to travel

- Solutions:

- Removed expired and unnecessary items

- Identified where supplies should be located in each exam room

- Organized things where needed

- Used visual signs to show when supplies were running low

- Standardized the workflow to minimize the retracing of steps

- Results:

- Reduced the number of steps taken by staff from an average of 360 to 52, —an 85% improvement—making the work more efficient

- Improved patient satisfaction and experience

- Created more space and maintained an organized department

In the pursuit of excellence, a large hospital in Chicago considered world-class by many standards, chose to transform with the implementation of Lean Principles and 5S.

Before being introduced to Lean, the Pulmonary Function Testing (PFT ) lab did not recognize that staff motion was waste. However, after understanding Lean, the lab was able to eliminate inefficiencies, optimize workflow, and ultimately improve patient care. This article describes their experience, highlighting the challenges faced, the solutions implemented, and the remarkable results achieved.

For years, the PFT lab operated in a state of chaos, unaware of the time wasted searching for supplies. This made it difficult to take care of patients quickly. They realized they needed to make changes and appointed Angela Douglas, the Administrative Coordinator for the PFT lab, to lead the project. Elizabeth Mora was selected as a key project team member. The goal was to reduce waste and create a high-functioning work environment where they could provide quality care on time.

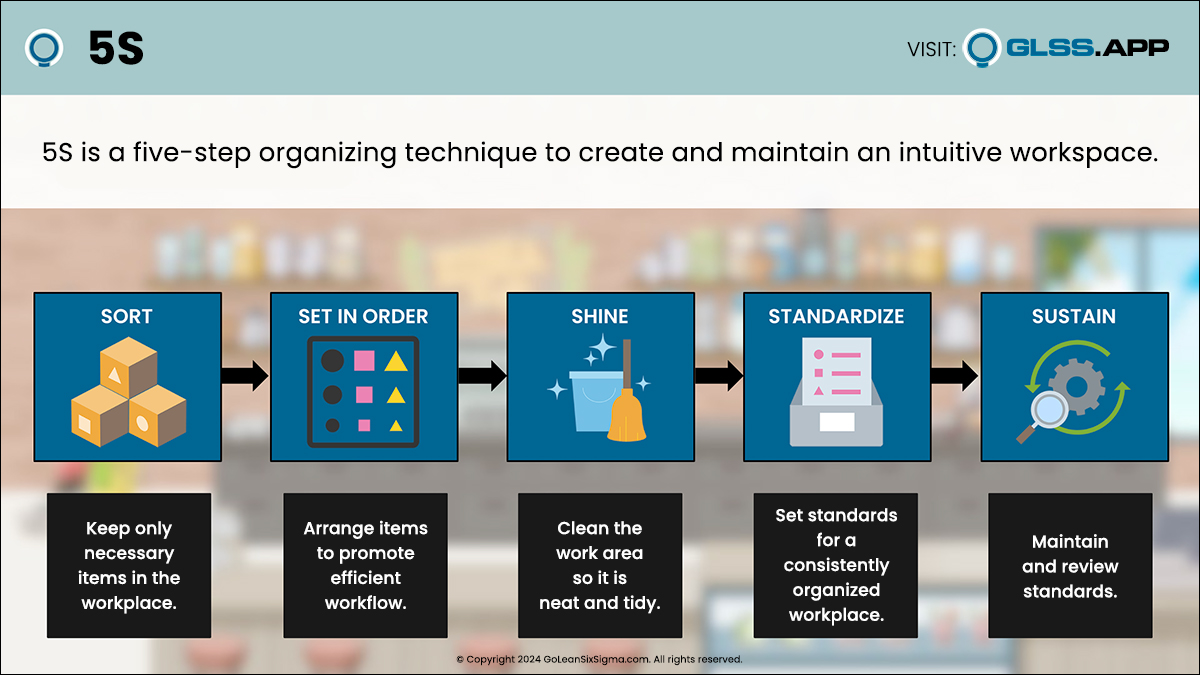

Angela says, “At first, we were not sure if we needed to change anything. We thought everything was fine. But we didn’t realize how much time we wasted searching for supplies and how it affected our work. We learned about 5S, which is a way to make things organized and efficient. We wanted to make our department better and create a place where our staff and patients could work well together.”

“We didn’t realize how much time we wasted searching for supplies and how it affected our work… We wanted to make our department better and create a place where our staff and patients could work well together.”

Angela wanted more tools and skills to lead the improvement project, so she chose GLSS Green Belt Training & Certification. Angela says, “With the GLSS training, I learned the step-by-step approach of DMAIC and found it very helpful. I loved learning how to complete the project phases and knowing what to do at each Tollgate. The training broke it down into manageable steps so I knew what to do next. Also, the case study used throughout the training was a great example of how to complete a project.”

As Angela led the team through the project, they discovered reducing waste would greatly enhance the department. They realized each person had a role in achieving operational excellence. The PFT team discovered that inefficient processes, wasted motion, unused supplies, and disorganization were causing problems. They didn’t just want to tidy up; they wanted to create a workplace that was efficient and intuitive. To understand the problem better, they used a Spaghetti Diagram to see how much time and motion was wasted looking for supplies. They also counted the steps taken by staff using pedometers.

To solve the problems, the PFT team used Process Analysis, the 8 Wastes, and 5S to develop solutions:

- Elimination of unnecessary steps: The team focused on streamlining processes and removing any unnecessary activities that hindered workflow.

- Supply organization: The department organized the supplies by doing a thorough inventory check, removing expired items, and labeling the supplies in each exam room. This made it easier to find what they needed.

- Standards and cleanliness: They set standards for cleanliness and made sure the work environment was always organized and tidy.

- Visual management: Visual cues were used to show when supplies were running low so they could be restocked on time.

- Training and continuous improvement: Staff members were trained on the new Standard Work and implemented a 5S Assessment checklist to track progress. They use regular team huddles and 5S audits to keep improving.

The changes made a big difference. Some notable results include:

- Less wasted motion: By optimizing and organizing supplies, the team reduce the number of steps they had to take.

- On average, they went from 360 to 52 steps—an 85% improvement.

- The total distance covered by staff members decreased from 1,098 feet to just 178 feet.

- Happier patients: With less time wasted searching for supplies, the team could focus more on taking care of patients, which improved patient satisfaction.

- A well-organized workspace: The department became fully organized and visually appealing, meeting all the requirements of 5S.

BEFORE AND AFTER

To show how Lean and 5S have become a part of the PFT lab’s DNA, Angela recalls, “Recently we added an iPad with software to help us communicate with non-English speaking patients. When it arrived in the department I immediately found a place for it and labeled it. My colleagues joked, ‘There she goes again… the Queen of 5S!’ But seriously, now we know that we need a place for everything and everything in its place.”

This project proves that even departments believed to be efficient can still improve. It shows how process optimization and reducing waste can make healthcare settings work better. This PFT lab’s journey can inspire other departments and organizations to improve efficiency, provide better patient care, and strive for excellence. And, who knows, you could even become royalty!