summary

Summary

Template

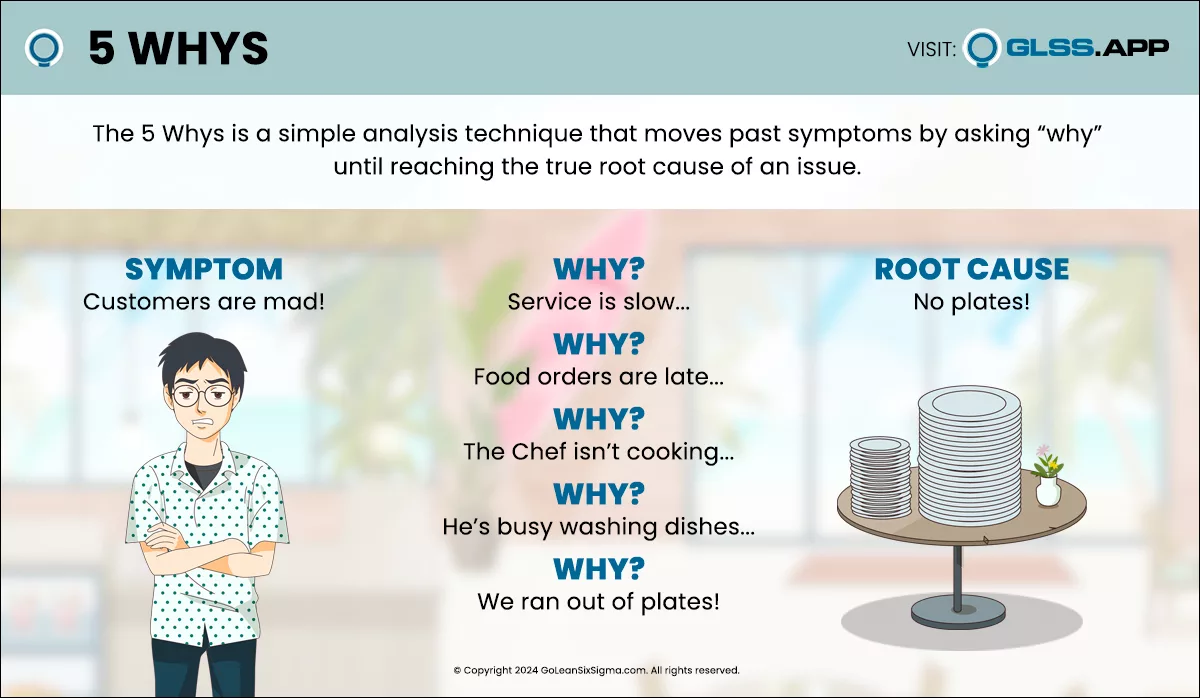

What are the 5 Whys?

5 Whys is a simple but effective method of analyzing and solving problems by asking “why” five times, or as many times as needed, in order to move past symptoms and determine root cause. This approach is used in tandem with Cause & Effect or Fishbone Diagrams.

To learn more about the 5 Whys, check out our Yellow Belt Training & Certification and Green Belt Training & Certification.

Or automate your Lean Six Sigma projects with AI using Kure.