summary

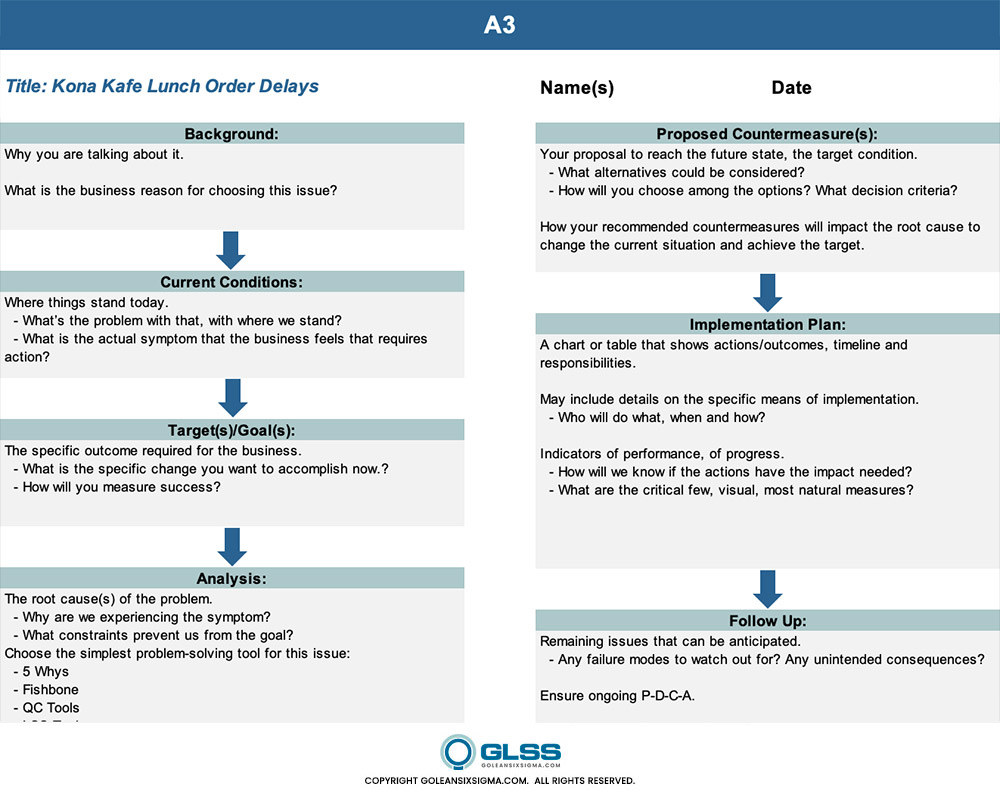

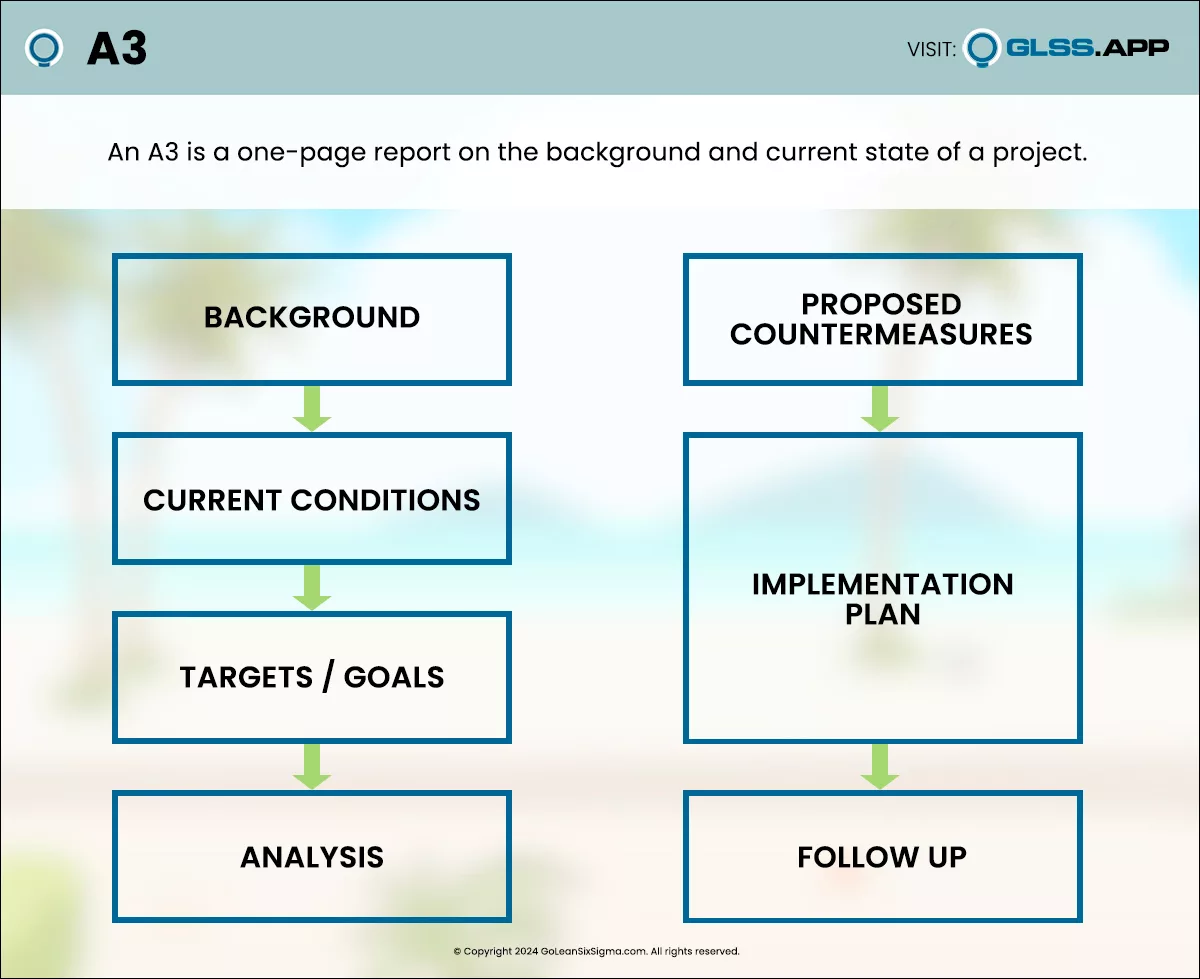

WHAT IS A3?

On a literal level, A3 refers to a ledger size (11×17) piece of paper. But in the Lean Six Sigma world, it is a tool to help see the thinking behind the problem-solving. Don’t mistake A3s as a document to be completed after the problem is solved. It’s important to use the A3 while working through the problem.

The practice of using A3s forces project teams to focus their efforts. At the same time, A3s make it easier for a leader or coach to review a problem solver’s work. A3s become valuable coaching tools since leaders can see and provide feedback on the problem solver’s thought process.

To get in-depth foundational training on how to complete Lean Six Sigma projects using A3s, check out our Green Belt Training & Certification!

Or automate your Lean Six Sigma projects with AI using Kure.