Lean Six Sigma (LSS) is a project management methodology. It equips organizations across the spectrum—from Fortune 500 giants to government bodies, nonprofits, and small- to medium-sized enterprises—with the tools to reduce costs, boost productivity, and deliver unparalleled customer value.

Every organization in every industry has processes to improve. We train teams to continuously improve those processes with LSS tools and techniques. In this article, we’ll explain how it works, using examples and benefits from a wide variety of LSS projects and implementations.

- What Is Lean Six Sigma?

- Six Sigma vs. Lean Six Sigma: What’s the Difference?

- What Are the Benefits of Using Lean Six Sigma?

- Lean Six Sigma Techniques

- What Are the Belt Levels?

- 5 Key Principles of Six Sigma

- Organizational Development and Lean Six Sigma

- Examples of Lean Six Sigma Usage

What Is Lean Six Sigma?

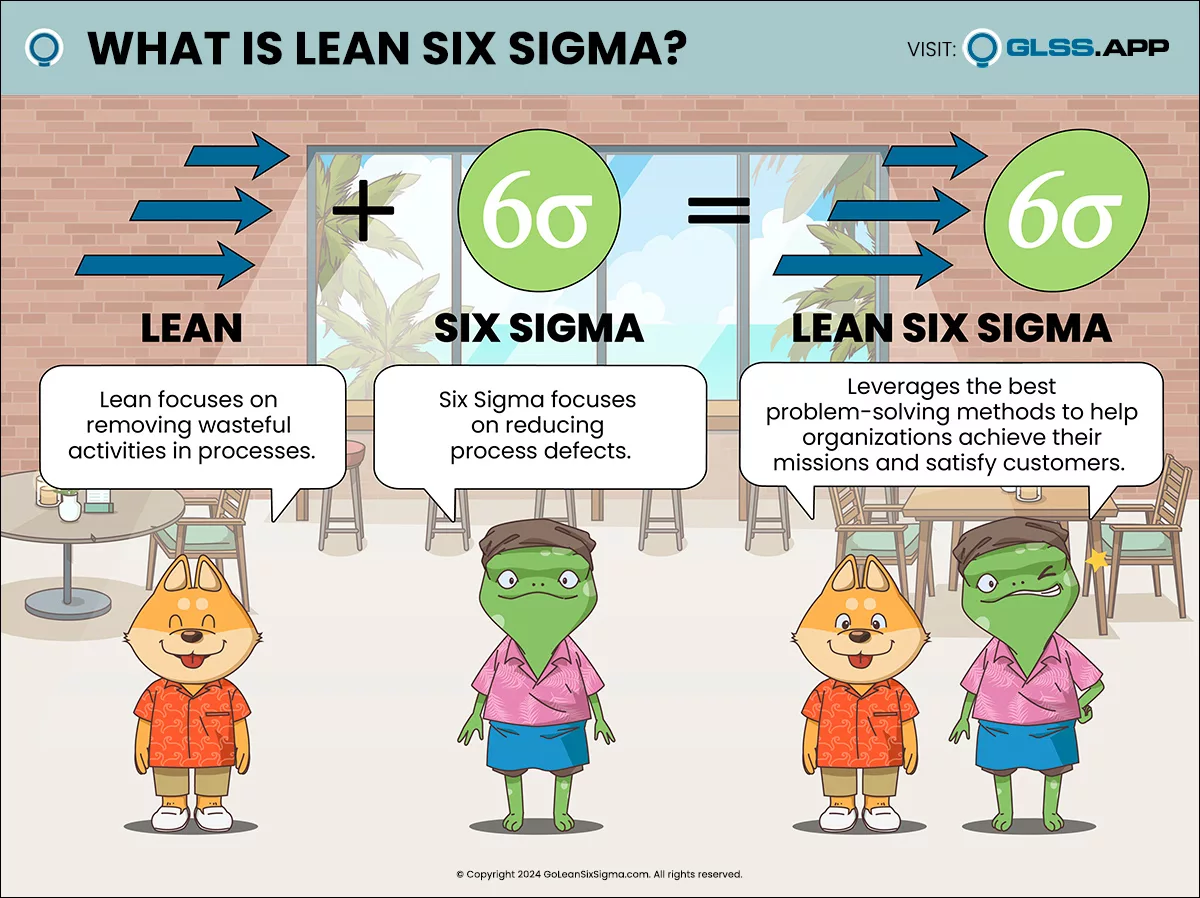

Six Sigma is a combination of two popular Process Improvement methods—Lean and Six Sigma—that pave the way for Operational Excellence.

Lean focuses on removing wasteful activities in processes. Six Sigma focuses on reducing process defects. Combined, Lean Six Sigma leverages the best problem-solving methods to ensure organizations achieve their goals and delight customers.

Before diving into details, it’s important to clarify the concept of Process Improvement.

Since Lean Six Sigma is a system for analyzing and improving processes, we’ll break down those terms first.

Six Sigma vs. Lean Six Sigma: What’s the Difference?

What Is Lean?

Originating in the 1940s, Lean methodology has been labeled a process improvement toolkit, a philosophy, and a mindset.

At its core, Lean is a popular approach to streamlining manufacturing and transactional processes by eliminating waste and optimizing flow while delivering value to customers.

What Is Six Sigma?

Originating in the 1980s, Six Sigma is a process improvement strategy that improves output quality by reducing defects. It’s named after a statistical concept where a process only produces 3.4 defects per million opportunities (DPMO).

Six Sigma can therefore be thought of as a goal, where processes not only encounter fewer defects, but do so consistently (low variability).

Combining Lean and Six Sigma Into Lean Six Sigma

These two methodologies are effective on their own, but when combined to make Lean Six Sigma, they’re incredibly beneficial.

Lean and Six Sigma are based on the scientific method, and together they support organizations looking to develop a problem-solving culture. This means that “finding a better way” becomes a daily habit.

Understanding both approaches and their accompanying toolkits is extremely valuable when solving problems. It doesn’t matter where a tool comes from—Lean or Six Sigma—as long as it does the job.

What Are the Benefits of Using Lean Six Sigma?

Organizations face rising costs and new challenges every day. Lean Six Sigma provides a competitive advantage in the following ways:

- Streamlining processes results in improved customer experience and increased loyalty.

- Developing more efficient process flows drives higher bottom-line results.

- Switching from defect detection to defect prevention reduces costs and removes waste.

- Standardizing processes leads to organizational “nimbleness” and the ability to pivot to everyday challenges.

- Decreasing lead times increases capacity and profitability.

- Increasing effectiveness through Process Optimization.

- Engaging employees in the effort improves morale and accelerates people’s development.

- Decreasing cost by removing waste and solving problems proactively.

- Improving efficiency by ensuring the best use of resources and process improvement plans.

- Developing effective people and teams by building the confidence and capabilities of team members.

Lean Six Sigma Benefits for Businesses

LSS works for organizations of any size. The same success achieved by large businesses can be attained by small and medium businesses. Smaller organizations may actually be more agile with fewer people and lower levels of red tape to navigate.

This method works for businesses looking for a roadmap to effectively meet their strategic goals. Applying it helps to increase revenue and reduce costs, while freeing up resources to add value where the organization needs them most.

Lean Six Sigma Benefits for Customers

The ultimate winners are the customers who receive consistent, reliable products and services.

Lean Six Sigma champions customer satisfaction by ensuring products and services meet the highest standards of quality and reliability. This methodology empowers businesses to exceed customer expectations through meticulous defect elimination and variability reduction.

Lean Six Sigma Benefits for Employees

Lean Six Sigma not only improves profit margins but also positively affects employees by engaging them in the work of improving their own processes.

Studies show that employees who feel they’re able to positively impact an organization will perform better, be more accountable, and live happier lives. By quickly mastering basic Lean Six Sigma skills, they’ll continually standardize work, root out problems, and remove waste in an organization.

Lean Six Sigma Techniques

Let’s walk through a sampling of the tools and techniques we use in LSS. During training, we work on improving actually processes in the organization. Individuals move through projects and learn on the job, seeing the impact of each successful LSS project.

Kanban

Kanban is a Japanese term that translates to “card” or “board” and indicates a signal within a process. Kanbans are part of Just In Time (JIT) processing, where either a physical or electronic device indicates that it’s time to order inventory, process a unit, or move to the next step in a process.

Kaizen

A Kaizen Event is also known as a Rapid Improvement Event.

Kaizen is a Japanese word that combines the ideas of “change” and “goodness,” which translates to “improve for the better.”

These events generally span from 1 to 5 days and involve key process participants focusing on solving a narrowly scoped process improvement opportunity. The difference between Kaizen and typical workshops is threefold:

- The planning for the event is extensive

- Leadership has given explicit approval for change

- The agreed-upon improvement takes place before the Kaizen event is completed

Value Stream Mapping

A Value Stream Map (VSM) visually displays the flow of steps, delays, and information required to deliver a product or service to the customer.

Value Stream Mapping allows analysis of the Current State Map in identifying barriers to flow and waste, calculating Total Lead Time and Process Time, and understanding Work-In-Process, Changeover Time, and Percent Complete & Accurate for each step.

5S Tool

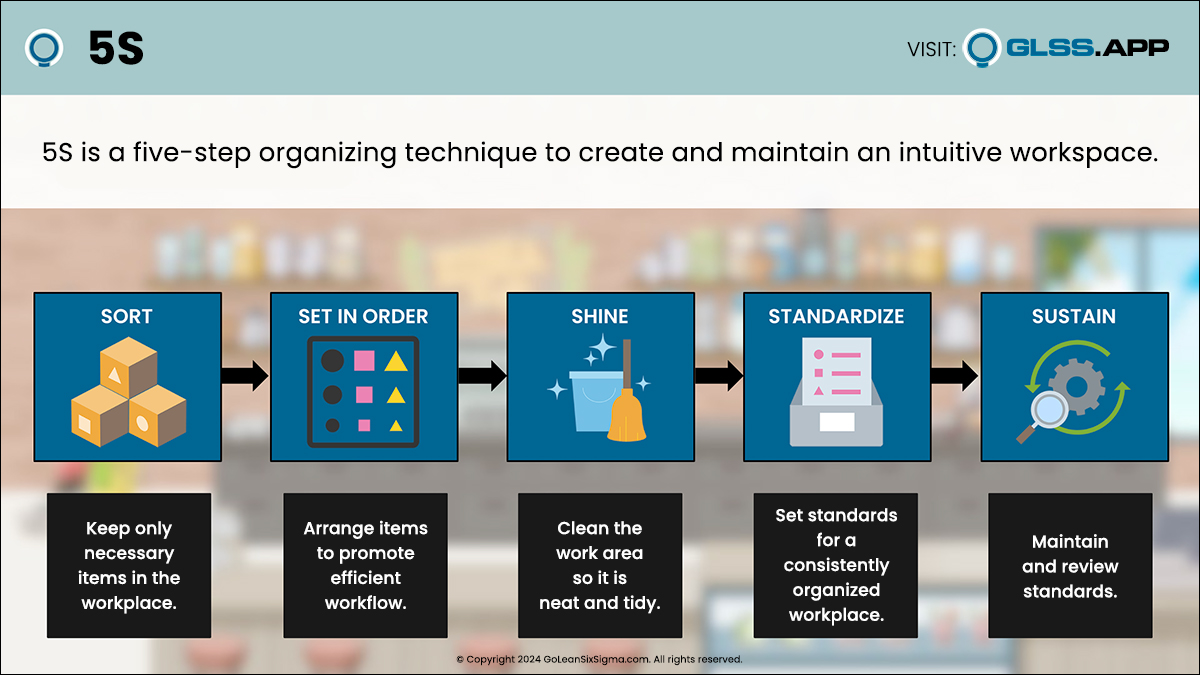

5S is a five-step organization technique to create and maintain an intuitive workspace.

The five steps are:

- Sort – Remove unnecessary items from the workplace.

- Set In Order – Arrange items so they are easily accessible.

- Shine – Clean the work area so it is neat.

- Standardize – Set standards for a consistently organized workplace.

- Sustain – Maintain and review standards.

What Are the Belt Levels?

In LSS, belt colors signify a change or advancement in the ability and responsibility of a person. Each belt has specific knowledge, training, and skill sets. By “ranking up” (moving to the next belt), the previous belt’s knowledge base is built upon with additional capabilities.

Each LSS project has different objectives and requirements, and the comprehension of a Green Belt may be as suitable for a project as a Master Black Belt.

At GLSS, we don’t require you to wait to complete a project or move to the next level. Our optimized approach makes it easy to continuously learn, apply, and advance. And you’ll be applying what you learn on projects you’re currently working on.

5 Key Principles of Six Sigma

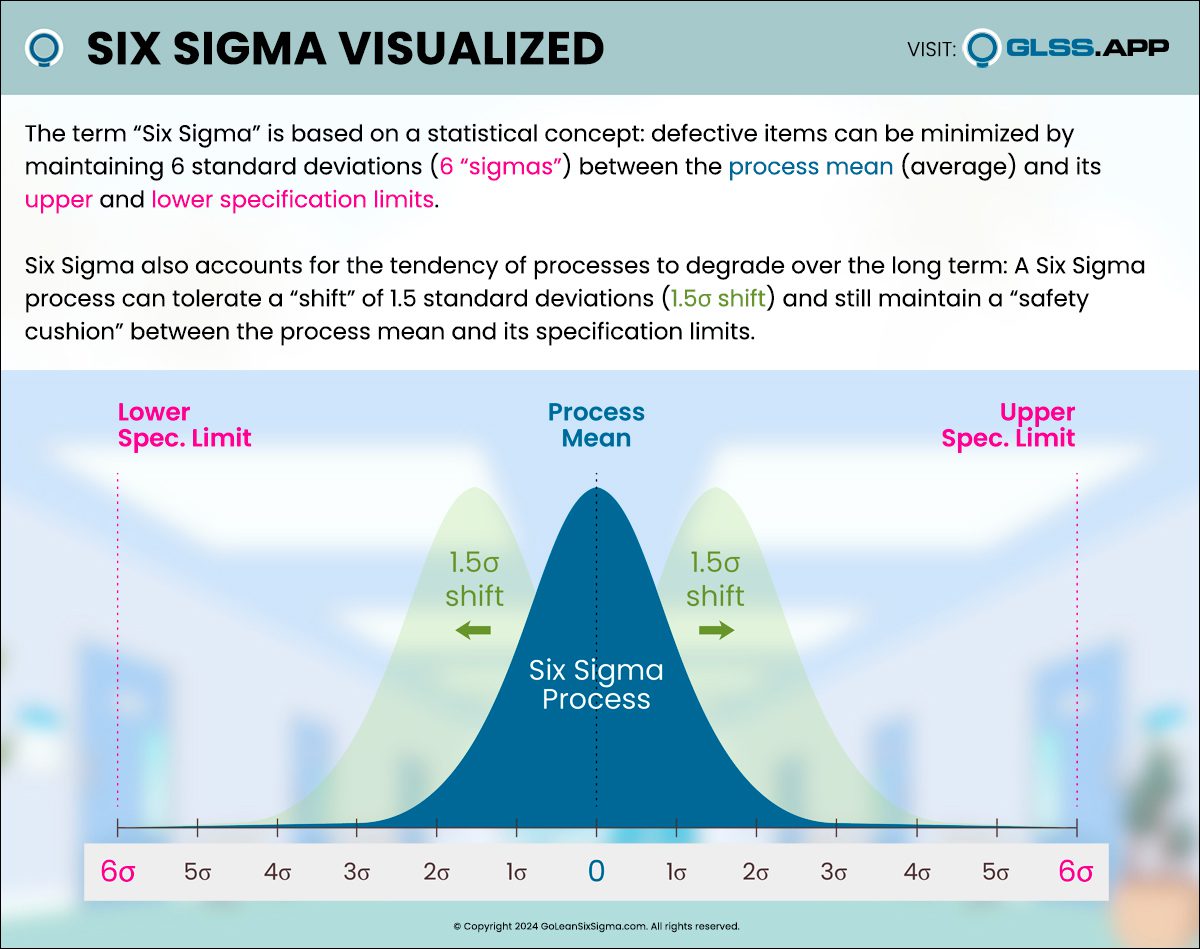

At the heart of Six Sigma lie five key principles. These principles are based on the statistical concept that defective items can be minimized by maintaining 6 standard deviations (6 “sigmas”) between the process mean (average) and its upper and lower specification limits.

Each principle helps guide organizations toward Operational Excellence. They also shape the methodology’s approach to Process Improvement and ensure that the journey aligns with the ultimate goal of enhancing value for customers.

1. Focus on the Customer

Six Sigma aims to meet and exceed customer expectations, ensuring that every Process Improvement effort is customer-centric. Organizations can tailor their processes to deliver superior quality and service by understanding what truly matters to the customers.

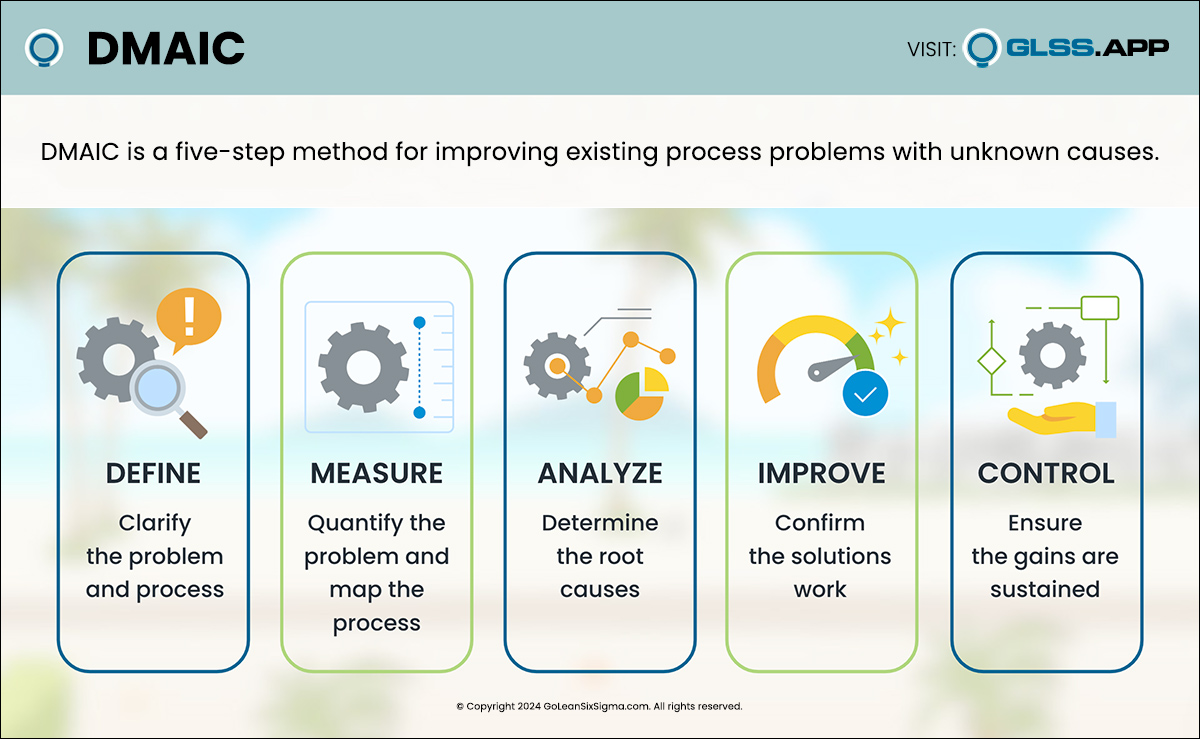

This principle echoes the Define phase of DMAIC (Define, Measure, Analyze, Improve, Control), where identifying customer needs sets the stage for meaningful improvements.

2. Measure the Value Stream

Mapping and measuring the Value Stream are crucial for identifying the flow of materials and information as a product or service progresses. This step highlights not only the value-adding steps but also exposes areas of waste.

It’s a blend of the Measure and Analyze phases of DMAIC, providing a data-driven foundation for understanding and improving processes.

3. Get Rid of Waste

Eliminating waste—anything that doesn’t add value to the customer—is a core objective of Six Sigma. Waste reduction is integral to process improvement, focusing on streamlining operations and enhancing efficiency.

This principle aligns with the ‘Improve’ phase, where targeted strategies are implemented to remove non-value-adding activities and optimize process performance.

4. Involve Stakeholders

Engaging stakeholders, including employees at all levels, fosters a culture of Continuous Improvement. Involvement encourages ownership and accountability, ensuring that improvements are sustainable.

This collaborative approach is vital during the Analyze and Improve phases of DMAIC, where stakeholder insights can drive deeper understanding and more effective solutions.

5. Ensure a Flexible and Responsive Ecosystem

Six Sigma emphasizes the importance of adaptability and responsiveness within processes. By building flexibility into systems, organizations can react swiftly to changes in customer demand or other external factors.

This principle underpins the Control phase of DMAIC, where maintaining process improvements and adapting to new insights ensure long-term success.

Incorporating these principles into the fabric of an organization’s processes drives toward Lean Six Sigma’s goal of reducing defects and waste and aligns efforts with the broader objectives of Process Improvement.

Process Improvement, fundamentally, is about enhancing an organization’s operations to be more efficient, effective, and adaptable. Working on a process involves analyzing, redesigning, and implementing changes to make it better, as opposed to working in a process, which is about performing the day-to-day activities within the existing process framework.

The DMAIC methodology offers a structured approach to handling process improvements, ensuring that efforts are focused, measurable, and aligned with organizational goals and customer expectations.

Organizational Development and Lean Six Sigma

Organizational Development (OD) is the application of the behavioral sciences to resolve organizational problems. Organizations succeed through the integrated functioning of people, processes, and technology.

OD practitioners understand that in order to support organizational change, it’s crucial to understand how the systems and processes of the organization are driven by complex factors such as behaviors and cultural norms.

Lean Six Sigma offers competitive advantages as a complement to Organizational Development, particularly when business transformation requires improvement of operational processes.

Motorola and GE are recognized for their successful implementation of Lean Six Sigma. But what’s often not highlighted is that both companies’ change initiatives started generating incredible business results when they combined LSS with OD techniques.

These organizations and others since have found that driving change and business results, comes from integrating the Lean Six Sigma toolbox with the broad and effective methods of Organizational Development.

Examples of Lean Six Sigma Usage

LSS, with its dual focus on reducing waste (Lean) and minimizing variability (Six Sigma), offers powerful strategies for tackling an array of challenges across various industries. Here are some examples illustrating its agility and impact:

Repairs

If your company experiences frequent equipment breakdowns, Lean Six Sigma can be used to analyze and improve the maintenance process.

By applying the DMAIC methodology, you can identify root causes of failures, such as inadequate maintenance schedules or the use of substandard parts, and implement corrective actions. This leads to fewer breakdowns, reduced downtime, and lower repair costs.

IT Downtime

For an organization suffering through regular IT outages, Lean Six Sigma can help by streamlining and standardizing IT operations.

Through Process Mapping and root cause analysis, IT teams can pinpoint vulnerabilities in their network infrastructure or software deployment practices. Solutions might include establishing more robust IT protocols, enhancing system redundancies, or improving incident response times, minimizing downtime, and improving system availability.

Manufacturing Defects

Manufacturers with the goal of reducing defects in their products can employ Lean Six Sigma to refine production processes.

By analyzing data on defect occurrences and using statistical tools to understand variability in manufacturing processes, companies can identify specific steps where errors are introduced.

Applying targeted improvements, such as adjusting machine settings or improving worker training, can significantly reduce defect rates, enhance product quality, and increase customer satisfaction.

Check out one of our case studies from Piston Automotive, showing actual results and see the benefits for yourself.

You can read about even more industry case studies to see how LSS can help your organization.

Environmental Impacts

Organizations looking to reduce their environmental footprint can leverage Lean Six Sigma to identify and eliminate waste in their operations.

This might involve optimizing resource use, reducing energy consumption, or minimizing waste production.

For example, by analyzing the entire lifecycle of a product, from raw materials to end-of-life, companies can find opportunities to use resources more efficiently, recycle more waste, or redesign products to be more environmentally friendly, thereby contributing to sustainability goals.

Each demonstrates how Lean Six Sigma’s structured approach to problem-solving and Process Improvement can be applied to achieve significant, measurable improvements in efficiency, quality, and sustainability.

Ready to Jump Start Your Lean Six Sigma Journey?

You’ve got an exciting road ahead of you, and an easy way to begin your adventure is by signing up for our free training.

Our new Lean Six Sigma Training will quickly introduce you and your teams to the basic elements of problem-solving using Lean Six Sigma. In doing so, you’ll increase customer satisfaction, while having a positive impact on your organization as a whole.