Surely everyone knows that process improvement has changed dramatically over the last 20 years, and certainly there are generational differences in the practitioners then and now.

The first post in this series, The Next Generation of Lean Six Sigma (Part 1): Then and Now, was about the generational shifts in process improvement. This blog highlights those shifts through the eyes of two certified Black Belts, Dodd Starbird and James Starbird, who also happen to be father and son. Let’s dive right in the conversation on how they uncover new vs old tools and how we’ve come into the next generation of Lean Six Sigma.

They work together today at Implementation Partners LLC, a consulting company that blends classic process improvement techniques with newer tools to help clients build Engaged Team Performance (ETP). Dodd Starbird is a certified Master Black Belt and did his Black Belt training “right before it was cool” in 2000. James Starbird received his Black Belt Certification from GoLeanSixSigma.com in 2017.

A Fireside Chat

Today they’re sitting by the fireplace in a small town tucked deep in the Colorado Rocky Mountains as they discuss today’s topic, Old Tools for a New World.

James: Hey Siri, run a regression for me.

Siri: “One moment. Hmmm. I’m not finding anything for ‘run regression’…”

James: Dad?

Dodd: What?

James: Are we there yet?

Dodd: You got me. At every moment in history, someone has probably said something silly like, “Everything that can be invented has been invented,” or today maybe, “My computer does everything I need it to do.” And then shortly thereafter, they’re proven wrong. That said, most people probably know that the vast majority of Lean Six Sigma tools are decades old, and many people probably think those tools work just fine.

For me it’s like sitting next to a wood fire; there’s something about the real thing that you just don’t get from a gas fireplace. It probably has something to do with getting back to the basics and building the pile of logs by hand. Sometimes, the old ways are the best.

James: I know what you mean, even if you did steal that last part from a Bond movie. Some things don’t need to be changed—they’re fine the way they are. However, I’m happy we didn’t have to chop down the wood for the fire. That might’ve been a bit too old-fashioned for me. Similarly, I can appreciate how many Lean Six Sigma methods have transformed over the years to streamline the change process.

“Use Every Tool” vs “Use What Works”

Dodd: I agree with you there. One major change has been how the methods are used. As we discussed in our last post, thirty years ago almost all of the experts were versed in Lean or Six Sigma, but there were few people practicing a combination. Even fewer people were picking and choosing what to use from the great number of principles and tools.

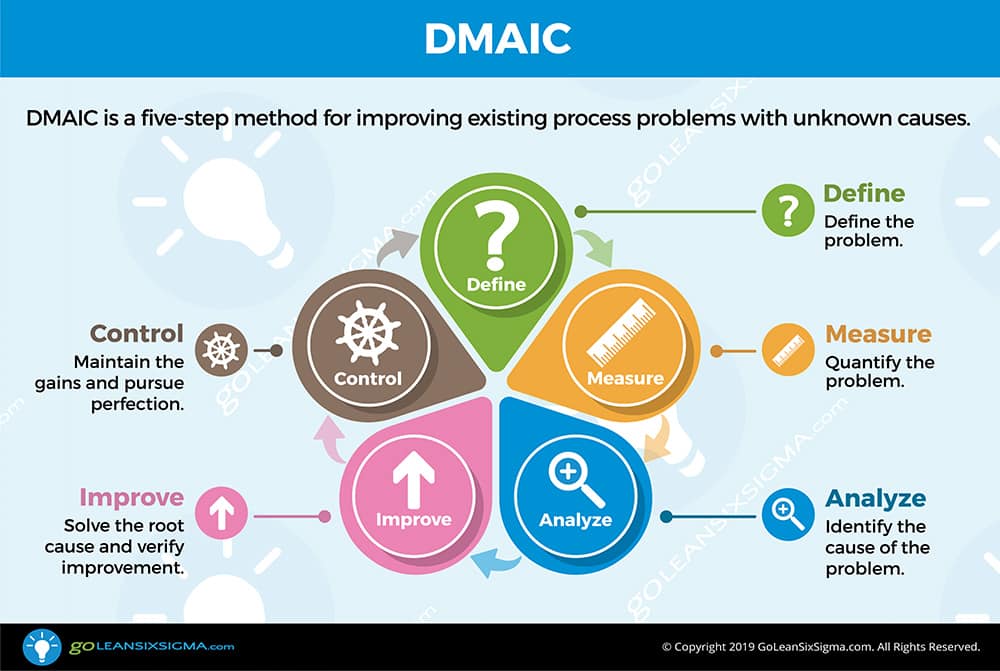

Certification requirements often demanded demonstration of a large complement of tools, even if they didn’t all fit well with the person’s assigned project. So we all followed the Define-Measure-Analyze-Improve-Control (DMAIC) steps in a linear way (which is exactly the right way to do it), but also tried to use every tool on the list in order to show that we had done the project diligently.

James: Seems like a little bit of overkill. Nowadays we teach people to only use what they need. It’s kind of like one of those cooking shows on TV—when you’re starting out as a new chef, you definitely need to use a cookbook, but once you know the tools by heart, you can combine them and improve upon them without referring to the recipe every time.

Although we think all of the tools are valuable some of the time, there is certainly a time and place for each of them. Just like the TV chefs, though, you have to know the right techniques by heart in order to think on your feet and combine them to make something good before time runs out.

Dodd: We always said back in the day, “We teach Lean Six Sigma linearly through the DMAIC process, but we execute it iteratively.” The problem was that we were so focused on driving the systematic deployment through organizations that we often forced everyone to demonstrate every tool, so at times it felt pretty inflexible. The approach got the reputation for being slow instead of agile.

James: And then an approach called Agile actually grew out of Lean. It’s funny how innovation always finds a way!

Dodd: True, true.

James: But we still use many of the same tools today, right?

The Next Generation of Lean Six Sigma As An Operating System

Dodd: Sure, here’s an example: when I meet a new client for the first time and listen to their needs for a project or transformation, I often will ask about their business processes and write post-it notes on the conference room table with the process steps as they describe them.

When they’re done, there’s usually a hybrid of a process map in front of me, in the Suppliers-Inputs-Process-Outputs-Customers (SIPOC) format, but with more process steps than a typical SIPOC. It’s funny, because I don’t label the columns or even tell the client it’s a SIPOC, and I’m not doing it to teach them anything. I just think using Lean Six Sigma tools! It’s my operating system.

James: I think the biggest difference is actually the capabilities that are available now in Excel and other tools. And I’m not talking about just replacing statistical tools from more-complicated software applications; I’m saying the existing tools have gotten better at helping us manage, analyze, and display data. Sometimes the training materials haven’t kept up with everything we can do—so much so that we recently had to create a supplemental 3-day course to just teach advanced Excel skills.

Dodd: Very true. Some of those original training materials were developed two or more decades ago, and some haven’t evolved as applications like Excel developed greater capabilities. I think when I first learned Excel, it was called Lotus 1-2-3? I know you’re going to tell me that the world is moving on, but we’re still using a lot of those Excel capabilities that have come along in the last 15 years—everything from conditional formatting and data validation to assisting people in filling out data collection forms, to using pivot tables and SUMIF functions to aggregate data for analysis.

We still use the statistical tools when needed, of course, but Excel allows us to quickly manipulate, scrub/prep, analyze, and display results, and then we migrate the data to other applications as needed. That said, we’re also starting to see other data manipulation and display tools like Tableau, which allows us to automate the data analytics for the Control Phase of projects. Those applications are more powerful and produce nicer outputs.

James: Now that sounds truly old-school! Yes, the world is moving on. These days, we’re using a combination of different tools to get the job done. Similar to how we pick and choose between Lean, Six Sigma, and Agile, we pick and choose platforms based on what tool is best for the job. Most of the platforms have become so dynamic that they can be implemented together or used interchangeably.

For instance, we can create a dashboard concept in Excel, use PowerQuery to source the data and perform a simple extract-transfer-load (ETL) to understand how it interacts. And when we’re ready to scale it, we take the same code we’ve built and import it directly into Power BI, an analytics tool similar to Tableau, to develop our finalized product.

This allows us to get to know that data in a platform everyone is comfortable with while also allowing scalability and reusability. So no work goes to waste, and we don’t have to recreate anything from scratch. Sounds like something out of a Lean or Agile case study, right?

Dodd: True. As long as we can originally create and translate our work in a way everyone understands, we can provide real value for everyone involved. And if we can teach new skills while we do it—even better!

A wise person once said, “If you can make it in Excel, you can show the developers what you want them to develop. If you can’t make it work in Excel, you probably don’t know enough yet about what you want them to do anyway.”

James: You’re right. Keeping it as simple as possible in the beginning is always a good idea.

Leveraging the Next Generation of Lean Six Sigma Tools in Transactional Environments

Dodd: Another application where we’ve leveraged Excel and some of those newer tools is the way we do time studies today in transactional environments. Back in the day, we had to send someone to stand and watch people do the work, but because everyone now has Excel, we created some self-reported time study worksheets that we can give to everyone in order to gather a more representative sample of the work. While seemingly a painful exercise to get the entire team to collect data, it also engages everyone in the project. And you learn some pretty amazing things.

James: Occasionally we can even get those process timings directly out of a workflow system, as long as we check to make sure we are getting clean data and not misinterpreting a long lunch as a long task when the system is left open for a while. We sometimes have to remind people that just because the data is easily available, doesn’t mean it should be used. Data availability should never trump data quality!

Next time, let’s dig into those time studies and share some of those new-school techniques where we apply old-school industrial engineering concepts. Talk soon!