Food Processing Equipment Manufacturer Saves $240,000 In Annual Warranty Claims With GLSS

Home » Case Study » Food Processing Equipment Manufacturer Saves $240,000 In Annual Warranty Claims With GLSS

Iceland

Manufacturing

Warranty

$240,000

PROJECT SUMMARY

When it comes to large equipment purchases, a warranty matters.

The knowledge that customers will be protected from defects is often the difference between winning them over or losing a sale. But warranty claims can also take a big chunk out of a company’s bottom line – especially if they’re not handled efficiently.

So how does a manufacturer keep its warranty costs under control without alienating its customers? By empowering a community of problem solvers capable of building a culture of operational excellence and continuous process improvement.

Our online Lean Six Sigma training makes it easy to apply process improvement and deliver tangible results. Read on to learn how GoLeanSixSigma.com’s training enabled a leading food processing equipment manufacturer to reduce its annual warranty costs by $240,000.

It was Marel’s policy to automatically approve and pay any warranty claim not processed within the customer-promised 60-day time frame. Unfortunately, the company had been missing its deadline in 13 of the last 18 months. That poor performance translated into a lot of unnecessary payouts.

Magnús Ívar Guðfinnsson I, Marel’s Global Service Excellence Manager and the process owner for quality, warranty, service, and customer experience processes, was surprised by the large gap between process performance and the 60-day goal. He decided to solve the problem by turning it into a Lean Six Sigma project.

That warranty claims process in use at the time had only been implemented in 2017, making it relatively new. Employees on the Global Warranty Team (GWT) were not aware of the performance issues. But once informed, they were immediately on board with the need for change.

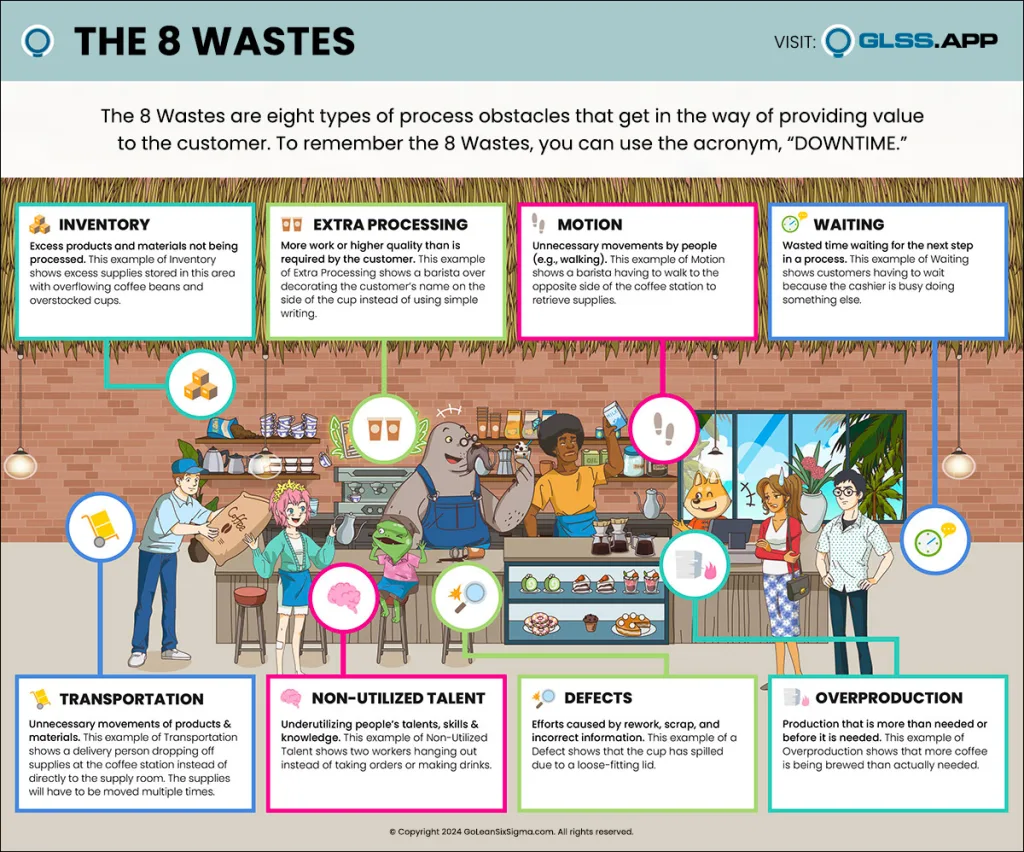

Magnús and the team conducted a Process (Gemba) Walk in three separate locations to gain deeper insight into the time gap. They documented wastes using the 8 Wastes Check Sheet and identified improvement opportunities during the walk. As the team interviewed process participants, they learned how the claims process truly worked and were surprised at the variation across the different company locations.

The most common wastes they observed were Extra Processing, Defects in recording information, and Waiting for information. They also noted confusion among the staff regarding their individual responsibilities.

But the team’s most significant discovery? How little the GWT communicated with other colleagues in the process. They assumed other participants knew how to work within the warranty process and operate the IT system – but that wasn’t the case.

“When this process was implemented, the focus was on the technical side, not the no-less-important ‘soft’ issues like communications and training,” Magnús recalls.

The team was able to formulate targeted solutions once they realized just how essential communications, training, and Continuous Improvement are for the long-term success of the warranty claims process:

- Clarified the roles and responsibilities of the functions involved

- Created Standard Work and Visual Management to communicate the procedures and expectations

- Trained all colleagues on the end-to-end process, including the IT system

- Empowered staff to take action and avoid waiting on decisions and approvals

The team’s improvements quickly produced measurable results:

- Warranty claims with returned parts went from 68 days to 43 days – a 37% improvement

- Warranty claims without returned parts went from 13 days to 5 days – a 62% improvement

Their Lean Six Sigma project cut overall cycle time and bolstered the effectiveness of determining claim validity. As a result, their customers now enjoy a quicker, more professional experience when filing a claim.

Meanwhile, Marel realized $240,000 in annual warranty costs savings. The tighter process also required one less person to process claims, resulting in a $50,000 yearly savings and the ability for the employee to redeploy and focus on adding value for the customers.

“The process participants were thrilled to witness this improvement; everyone wants to work to the best of their abilities – that sure applied here,” Magnús recalls.

In the future, he plans to capitalize on this project with further improvements and apply the team’s new Lean Six Sigma learnings to other projects across the company.

“It is very fulfilling to tap into and engage colleagues’ know-how and competence in reaching new plateaus in organizational performance for the good of the company and the customer.”

The Lean Six Sigma approach to process improvement empowered the Marel team to clearly identify obstacles in their way, develop effective solutions, and quickly deliver tangible results.

Regardless of your process problems, GoLeanSixSigma.com’s training will help ensure your team starts its journey toward a culture of operational excellence and continuous process improvements.